Types Of Mechanical Keyboards

What makes a mechanical keyboard a

mechanical keyboard?

Well, there are a couple significant differences that

specifically mechanical keyboards have over your

standard rubber dome keyboard.

1. Mechanical keyboards do not require a key to be

fully depressed, or bottom out, in order to actuate.

Most use some sort of mechanism that allows the

circuit to complete before the key is fully depressed,

resulting in less force exerted on the fingers, as

well as a significant increase in typing speed for

those who have trained with lighter key actuation

force.

3. Mechanical are often much more durable than rubber

dome keyboards. Rubber domes degrade overtime and are

unserviceable when a key no longer functions. However,

mechanical keyboards are often made with discreet

modules or standardized parts which were designed to

be replaced. Also, due to the properties of the

materials being used (plastic and metal vs rubber),

they degrade at a much slower rate. Rubber domes last

about 10 million key presses per key, but mechanical

switches often last more than 50 million key presses.

Some have even been rated up to 30 billion keypresses!

3. Mechanical keyboards come in a very wide variety of

mechanisms or switches, usually variations of one of

two designs, The Cherry MX design (the most common) or

Alps Electric design. Some make an audible sound to

notify the typist that the key has actuated, while

others have a bump that is noticed after the key has

passed the actuation point. Other switches use rubber

to muffle the sound and use grease to ensure the

plastic on plastic surfaces don't have a scratchy

noise for a silent experience. Its quite staggering

the number of different switches out there.

So, for simplicity's sake, we will focus on three

different types of mechanisms: The Cherry MX switch,

the Alps Electric SKCM switch, and IBM Buckling Spring

switch.

Cherry MX Switches

US Patent 4467160A

This is what is commonly referred to as

the Cherry MX switch. If you were to go

buy a "mechanical keyboard" or "gaming

keyboard", chances are you would find

something that uses this switch, or at

least a derivative of its design. The

Cherry MX switch design is composed of a

couple core parts.

1.

The "keycap", the piece

of plastic that has the

letters or numbers

printed on it. Usually,

keycaps are changed for

cosmetic purposes, but

sometimes it brings

functional benefits,

such as allowing light

to pass through if there

is an LED back light.

The only real purpose

they serve is to provide

an idea of what key

executes what letter

when pressed.

2. The slider, which would serve a similar

function to the stem referred to in the

rubber dome page. However, in modern

designs, the stem is given a standardized

shape in order to replace the keycaps. The

slider may also be comprised of multiple

parts, such as the "click jacket" which is

in the above design. The "click jacket"

produces the click sound, usually after

but rarely synchronized key actuation.

3. A spring, which provides the return

force for the switch. The springs can be

weighted differently to improve actuation

speed via reduction in actuation force.

4. Metal contacts, which connect to the

PCB that the switches are attached to, as

well as provide a path for the electrical

signal to pass through.

US

Patent

4467160A

So, you can

see that in

this design,

bottoming out

isn't required

for the key to

actuate. Since

the slider

redirects the

downward force

horizontally

with angled

contacts like

so:

This is pretty

significant,

seeing as

rubber domes

require

bottoming out.

This means

that the

typist is less

susceptible to

mashing the

keys and

exerting more

force than

necessary once

they are used

to the

actuation

force. While

it would take

a bit of time

to break the

habit of

bottoming out

the keys,

another

extremely

useful feature

is the "click

jacket", which

produces a

clicking noise

after a

certain amount

of force is

applied. By

associating

key actuation

with a sound

or physical

change in key

feel, the

typist is able

to improve

typing speed.However,

the more

significant

part of this

switch is the

spring! So,

unlike the

most common

keyboards,

which are

comprised of

one large

rubber dome

mat that are

not

adjustable,

Cherry MX

switches come

in several

different

configurations.

This includes

springs of

different

spring

constants!

* NOTE *:For

sake of

simplification,

keyboard

actuation

force is

generally

measured in

gram-force

(gf), so

springs are

generally

described in

terms like "55

gram weight"

or "55 gram

springs"

(Fylladitakis,

2016). This

doesn't have

to do with the

spring's

actual mass,

but rather

describes the

spring

constant in

terms that are

easier to

conceptualize

as opposed to

the typical

unit of N/kg

which usually

describes the

spring

constant per

Hooke's Law

(F= -k * x,

from Knight,

2018)). In

reality, gram

force is

somewhere

around 0.98

centi-newtons

(1 cN = 0.01

N) per 1

gram-force or

1.02 gf per 1

cN.

Calculations

are much

easier if we

assume 0.01 N

= 1

gram-force.

For example,

if we put a

spring that

requires 0.55

N to actuate,

then our ever

diligent

computer

programmer

experience(0.55

N) * (5

letters + 1

space) * (60

words per

minute) = 198

N per minute

or 3.3 N per

second

8

fingers * x +

2 fingers

*(0.5x) = 3.3

N per second

9 fingers * x

= 3.3 N per

second

x = 3.3 N per

second/ 9

fingers =

0.367 N per

finger per

second

(0.367

N per finger per second)

* (9 fingers) * (60

seconds / 1 minute) *

(60 minutes / 1 hour) *

(8 hours)

=

95,040 N or 95.04 kN per

work day

Now, while this

particular spring

results with more force

than the laptop rubber

dome calculation, this

result is still lower

than the standard

desktop rubber dome,

while also being more

consistent over time.

This is due to the

allowance of

"over-travel", or the

space between key

actuation and bottoming

out, resulting in the

fingers being cushioned

instead of running into

a stiff resistance upon

actuation, as well as

less time needed to

return the key to its

initial state to be

actuated again.

While the actuation

distance can also be

changed, from the

typical 2mm of key

travel to 1.2 mm key

travel found in some

"gaming keyboards", both

modifications serve a

similar purpose.

Springs, in fact, are

actually much easier to

replace than adjusting

the design of the metal

contacts. Some keyboard

enthusiasts even replace

each spring individually

to fit their

preferences!

However, the Cherry MX

switch is not the only

mechanism with these

advantages.

Alps SKCM Switches

*Note*:

This is an Alps Clone switch called the NEC Blue,

which share an extremely similar mechanism.

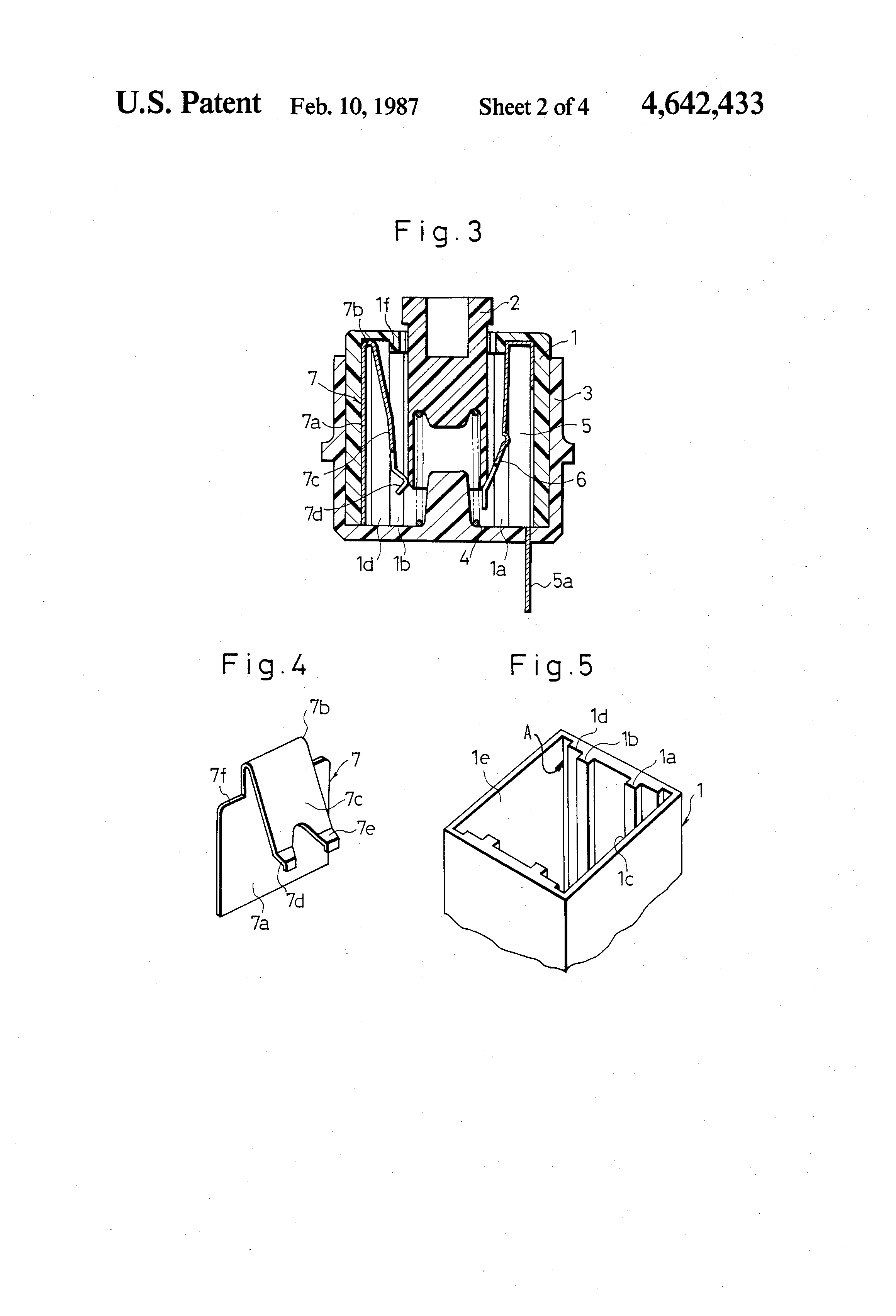

US Patent 4642433A

The Alps design, while mechanically

different from Cherry MX switches, offers

very similar advantages and a few others

that Cherry MX lacks.

The basic parts are nearly identical,

simply having different designs, such as

the metal contacts being on the same side

of the switch housing rather than opposite

sides, or the slider being rectangular

rather than a cross point.

Lets examine that slider a bit more. Now,

while I don't have a great picture of an

actual Alps Switch slider, the very first

picture shows an Alps switch clone that

has a slider that is inspired by the Alps

switch. Notice how the stem is elongated

and has a thin plastic post in the middle.

This stem offers a key advantage over the

much thinner Cherry MX stem in that it

reduces torque like the laptop scissor

switches before.

* Note *:

This is a

rubber dome

switch, but

the concept of

torque is the

same

By making

the stem

wider, torque

is reduced by

spreading the

force evenly

and directly

above the

slider,

reducing

friction.

While Cherry

MX tends to

have less

friction than

rubber domes,

many

enthusiasts

claim that all

MX designs

"feel

scratchy",

referencing

the uncommon

key binding

that some have

experienced

with the

switch (Fylladitakis,

2016). Modern

Cherry MX

switches

sometimes use

lubricant to

alleviate

this, while

the Alps

Switch's wider

stem and

simpler

construction,

such as using

a leaf spring

to provide

tactile

feedback along

with the click

sound rather

than a

deformation on

the slider,

seem to solve

this issue.

Check it out

below.

US

Patent 4642433A

The Alps Design was not without flaws

though. Though it was fairly easy to

service (or modify for enthusiasts), the

switch was rather sensitive, sometimes

with only a little powder rendering a

switch defunct permanently unless it was

meticulously cleaned. Despite lacking the

preference of typists, Cherry MX became

more mainstream and edged Alps Electric,

the company which owned the original Alps

Switch patent, out of the keyboard space.

The only modern Alps switches are clones.

However, there is a switch that exists

which many consider to both designs,

despite being older than both!

IBM Buckling Springs

US

Patent

4118611A

Due

to the

rotational

motion as a

result of the

buckling

spring, the

flapper

rotates rather

fast, creating

a clicking

noise once it

hits the PCB

and plastic

membrane. From

a mechanical

standpoint,

its pretty

cool how the

previous

designs

required

around 6 to 8

parts, this

one does it

with a

fraction of

the parts!

Shows how well

a simple

understanding

of physics and

design can go

a long way!

It's durable,

serviceable,

and doesn't

suffer from

the same

friction

issues from

previous

designs to to

the massive

stem

thickness. The

only real

disadvantage

was that it

was more

susceptible to

water damage

due to the

lack of liquid

drain holes.

However,

the switch was

not made as

discreet

module, as

well as being

much louder

than other

switches,

which was less

preferred by

office workers

who wanted a

quieter work

space.

Ultimately,

IBM phased out

this design in

favor of the

less expensive

and quieter

rubber domes.

It was a sad

time in

keyboard

history, but

most

definitely a

step toward

the quiet

working spaces

of today.

So,

hope fully you

learned a

little bit

about

keyboards and

physics! If

you are still

interested in

other goodies

keyboards

sometimes

have, checkout

the Extras!

page.