How Steam Turbines Work

Steam turbines like water turbines are used to

generate electricity. Steam turbines require an outside

fuel sources such as nuclear power, coal power, and

burning natural gas, and they are much more common than

water turbines. Currently in the U.S., steam turbines

account for 88 percent of the electricity generation.

Steam turbines use water that is heated to extremely high

temperatures and converted into steam to rotate the blades

of the turbine.

Courtesy

of http://turbinegenerator.org/steam/steam-turbine-works

These steam turbines rely heavily on the second law of thermodynamics that states: energy has quality and quantity, and actual process occur in the direction of decreasing quality of energy. We cant forget about the first law of thermodynamics either that states: energy can be neither created nor destroyed during a process.

1)

A heat source is needed which is usually provided by the

combustion of fossil fuels.

2)

This part of the figure is the boiler which uses the heat

energy provided by the heat source to convert water into

high pressure steam.

3)

An exhaust pipe is needed to exhaust the pollutants from

the combustion of the fossil fuel. This is not needed if

solar energy is used for heat conversion.

4)

The steam from the boiler is now pumped into the turbine.

The steam energy is used to rotate the turbine blades.

5)

Just like the water turbines, the steam turbine is

attached by a shaft to a generator to create electricity.

6)

The used steam now passes through and is cooled using a

cooling tower.

7) The

cooling tower releases the already used, lower energy, and

cooled steam into the atmosphere. The remaining

water that is cooled back into a liquid state is pumped

back into the boiler and repeats the process again,

creating more energy from steam. The is part of the figure

is crucial for the cycle. Some people wonder why you have

to waste that steam into the atmosphere or other thermal

reservoir. Steam power plant cannot run unless the cycle

is completed and heat rejection is part of this cycle.This

reason can be explained simply by the second law of

thermodynamics. This now lower quality steam cannot travel

back and be used again without violating the second law of

thermodynamics[1].

Diagram courtesy of

http://geothermal.marin.org/geopresentation/sld038.html

Two Main Types

of Steam Turbines

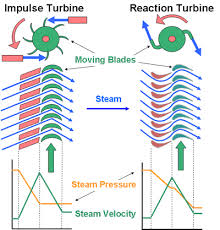

Like the name states impulse turbines run by the impulse of steam.

They have fixed nozzles that orient the

steam flow into high speed jets. These jets contain

significant kinetic energy, which the rotor blades, shaped

like buckets, convert into shaft rotation as the steam jet

changes direction. The velocity of the steam is then

reduced once it pass over the blades[4]

They have fixed nozzles that orient the

steam flow into high speed jets. These jets contain

significant kinetic energy, which the rotor blades, shaped

like buckets, convert into shaft rotation as the steam jet

changes direction. The velocity of the steam is then

reduced once it pass over the blades[4]"As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure, or more usually, the condenser vacuum). Due to this higher ratio of expansion of steam in the nozzle the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades is a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the "carry over velocity" or "leaving loss"[4]". Image above courtesy of http://powerplantstechnology.blogspot.com/2010/04/steam-turbine-use-in-power-plant.html.

Disadvantages of

Impulse Turbines-

The velocity of rotor

is to high for practical purposes

The velocity of the

steam is very when it leaves the turbine. So there is a

lot of energy wasted

These problems though

can be fixed with different expansion processes.

Reaction Turbines

In the reaction turbine, the rotor blades themselves are arranged to form convergent nozzles. This type of turbine makes use of the reaction force produced as the steam accelerates through the nozzles formed by the rotor. Steam is directed onto the rotor by the fixed vanes of the stator. It leaves the stator as a jet that fills the entire circumference of the rotor. The steam then changes direction and increases its speed relative to the speed of the blades. A pressure drop occurs across both the stator and the rotor, with steam accelerating through the stator and decelerating through the rotor, with no net change in steam velocity across the stage but with a decrease in both pressure and temperature, reflecting the work performed in the driving of the rotor[4].