The

Workings of a Water Turbine

Currently we are still using the basic desgins from

Francis and other past scientists. Over the last few

decades hydroelectric power stations have not been built.

This is because in the lower 48s the best and

largest locations have already been tapped into. It is

estimated that 75 percent of the potential water power of

the U.S. is already being used up. Alaska though is quite

different. less than 1 percent of the estimated 167

million kilowatts available in Alaska has been harnessed

to date[7].

How Water Turbines Work

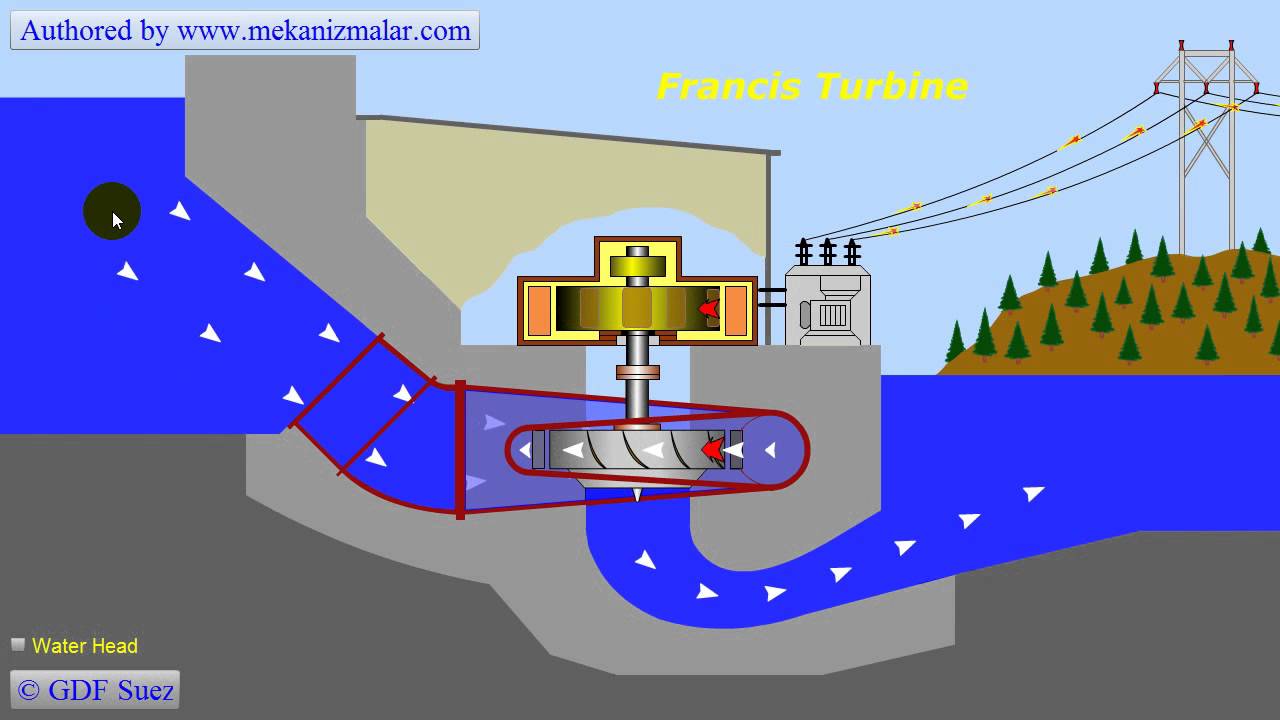

Water turbines rely on simple principles of

physics. The turbines use waters high flowing energy to

turn a blade that is connected to the shaft of a generator

to generate electricity. The figure above gives a basic

understanding of the parts of a hydropower plant.

Courtesy of

http://science.howstuffworks.com/environmental/energy/hydropower-plant1.htm

Dam- This part of the hydroplant holds back the

reservoir and contains massive amounts of potential

energy.

Intake- Hydrostatic pressure pulls the water through the penstock. The penstock is a pipeline that leads to the turbine. A penstock is what controls the rate and volume of water flow from a water source towards a hydro turbine generator. It is usually designed as a closed pipe with opening and closing gates to allow only the desired amount of water into the system[5].

Turbine- The water rushes in and strikes the large

blade of the turbine which is attached to a generator

above by a shaft. The most common type of turbine for

hydoplants is a Francis turbine. These turbines can weigh

as much as 172 tons and turn at a rate of 90 revolutions

per minute. Francis turbines are most used because

they are able to operate efficiently even  with large changes in flow rates.

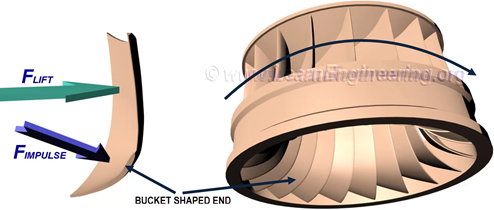

The blades of the Francis turbine are shaped precisely to provide lift.

When water flows over the blades, a low pressure will be

induced on one side, and high pressure on the other side. This

will result in a lift force. The blades also get another

help with rotation, and that is the impulsive force due to

the bucket shape towards the outlet. As you can see Newton’s

third law is being used extensively here. A spiral casing

is used on the Francis turbines to maximize flow energy.

When power needs vary the Francis turbines are equipped

with guide vanes to control flow rates and flow angle[5][6].

with large changes in flow rates.

The blades of the Francis turbine are shaped precisely to provide lift.

When water flows over the blades, a low pressure will be

induced on one side, and high pressure on the other side. This

will result in a lift force. The blades also get another

help with rotation, and that is the impulsive force due to

the bucket shape towards the outlet. As you can see Newton’s

third law is being used extensively here. A spiral casing

is used on the Francis turbines to maximize flow energy.

When power needs vary the Francis turbines are equipped

with guide vanes to control flow rates and flow angle[5][6].

Image courtesy of http://www.learnengineering.org/2014/01/how-does-francis-turbine-work.html

Here is a link to a good video on Francis Turbines:

http://www.youtube.com/watch?v=3BCiFeykRzo

Generator- As you should know from class, their are a series of magnets are turning inside the generator as the turbine blades turn. These giant magnets rotate past the copper coils to produce alternating current.

Transformers- Inside the power plant is a

transformer that steps up the voltage. Stepping up this

generated voltage depends on the number of turns on the

secondary coil. A step-up transformer can raise the

voltage by several hundred thousands volts.

,

,

Image courtesy of www.mekanizmalar.com

Important Factors for Hydro-Power

Now that you have learned the many parts a hydoplant, lets look at some key factors to maximize power generation.

Power = Gravity*Water Flow Rate*Head

Height

We are familiar with gravity of course,but not flow

rate and head height. The hydraulic head is the

distance that water flows from the higher elevation where

it is stored, to the hydro-turbine

generator. Hydraulic head is usually divided into three

categories: low, medium, and high head.

Elevations above around 100 meters are usually

considered high head, while low head system elevations

range around 10 meters in height. A high head hydro

turbine system requires less volume of water flow to

operate because the momentum collected from gravity

through the longer distance of falling water makes up for

the loss of volume.

The high head systems also require a smaller turbine

because of the lower volume of water flow needed.

A low head hydro turbine is usually used in a

flowing river with little elevation change, or in moving

ocean tides.

A low head system with a high volume of water usually

requires a much larger turbine generator to efficiently

convert the water energy into electricity[8].

Environmental Impacts

Although hydroelectric power is much cleaner compared to fossil fuel, it still poses risks to the environment. A dam can seriously alter the ecosystem near it. Dams have been known to help kill off fish species, because it is very difficult for them to migrate upstream even with a fish ladder installed. When the height of the water reservoir changes, it impacts the plants and animals that depend on that water[8].