The Physics Of Trusses

Trust the truss

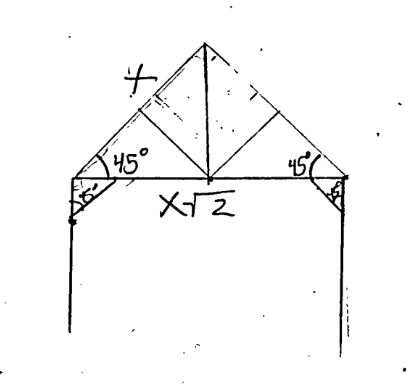

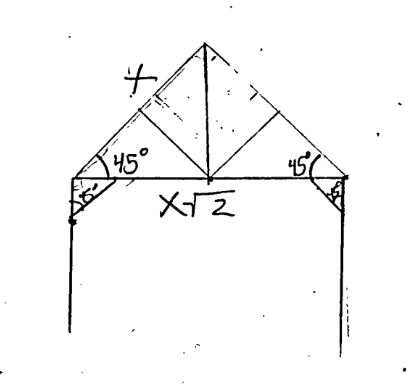

To the right, is an English Box

Truss. It is one of the more simplistic trusses that is used

in timber framing. There are variations where the timber

framer may curve all pieces with exception to the rafters

(the outside of the triangle) and the king post (the

vertical center piece). It is worth noting that this truss

is a right isosceles triangle. That means that each rafter

is the same length and this lends itself to the strength of

the triangle. Another common characteristic is that the

supporting members often connect in the middle of the

rafter. This is to ensure that the point load is directed

into the plate. The limitations of this truss is that you

must have a piece of timber that can span what ever length

is required to reach the breadth of the structure. Further,

the strength of the plate must be immense as it all

translates into the weakest point which is in the center of

the plate.

To the right, is an English Box

Truss. It is one of the more simplistic trusses that is used

in timber framing. There are variations where the timber

framer may curve all pieces with exception to the rafters

(the outside of the triangle) and the king post (the

vertical center piece). It is worth noting that this truss

is a right isosceles triangle. That means that each rafter

is the same length and this lends itself to the strength of

the triangle. Another common characteristic is that the

supporting members often connect in the middle of the

rafter. This is to ensure that the point load is directed

into the plate. The limitations of this truss is that you

must have a piece of timber that can span what ever length

is required to reach the breadth of the structure. Further,

the strength of the plate must be immense as it all

translates into the weakest point which is in the center of

the plate.

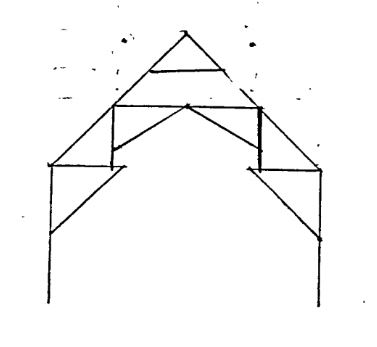

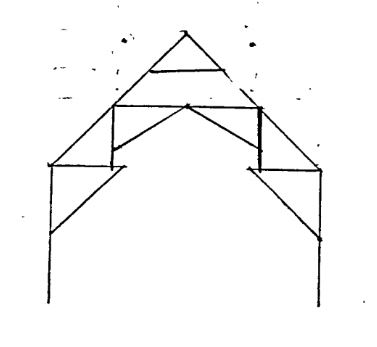

This is an example

of a hammer beam truss. You may not recognize it right away

but it is seen in much of our famed architecture such as

Westminster hall and Annenberg hall. The Annenberg hall may

not sound as familiar but it is also known as the Harvard

freshmen dining hall and was used as the model for the

Hogwarts dining hall.

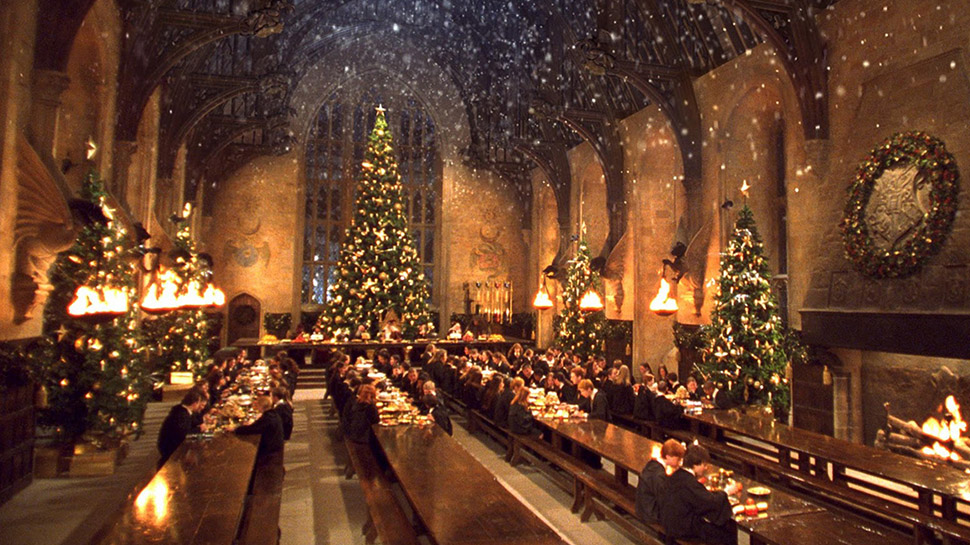

This is an example

of a hammer beam truss. You may not recognize it right away

but it is seen in much of our famed architecture such as

Westminster hall and Annenberg hall. The Annenberg hall may

not sound as familiar but it is also known as the Harvard

freshmen dining hall and was used as the model for the

Hogwarts dining hall.

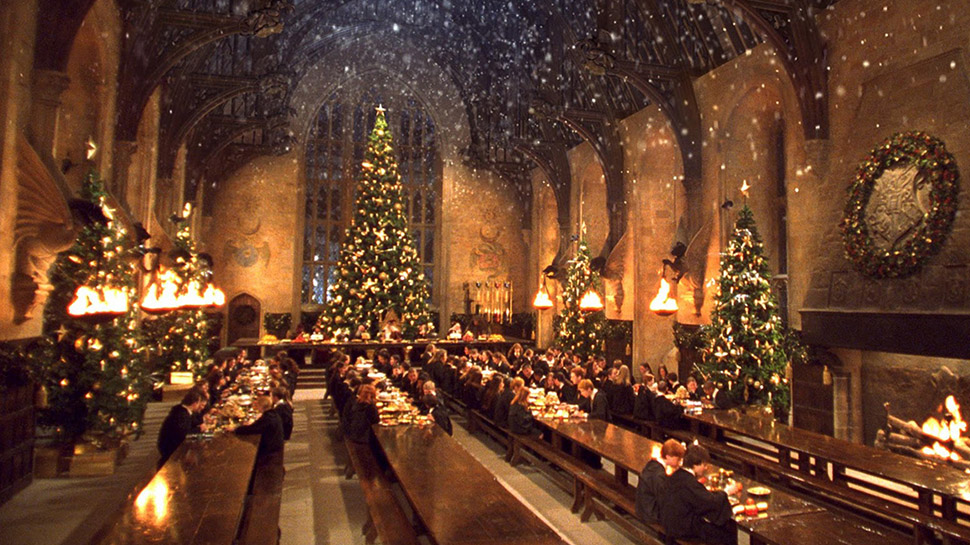

Within this photo

there is striking beauty due to the lighting, the vaulted

ceiling, and the gorgeously woven wood and stone work. Where

the curve hammer beams are resting on the stone masonry

work.

Within this photo

there is striking beauty due to the lighting, the vaulted

ceiling, and the gorgeously woven wood and stone work. Where

the curve hammer beams are resting on the stone masonry

work.

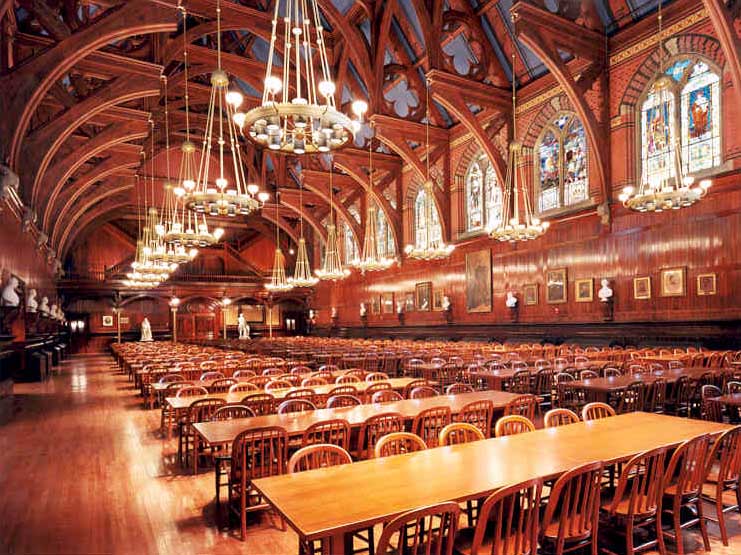

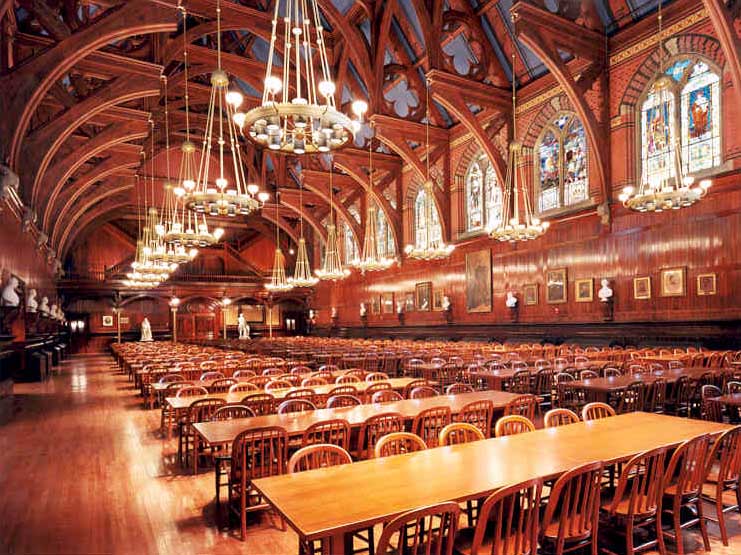

This is a real photo of Annenberg Hall. It is much brighter,

as there are windows, the masonry is actually wooden walls

yet the magical-ness is still there due to the vast span of

the room and also the vaulted ceiling.

This is a real photo of Annenberg Hall. It is much brighter,

as there are windows, the masonry is actually wooden walls

yet the magical-ness is still there due to the vast span of

the room and also the vaulted ceiling.

This image

demonstrates a 3D model and how it would have a point

loading in the center. Upon inspection you will notice

that Bay 2, in-between bent 2 and 3 is the smallest. This

allows for there to be less of a moment or torque placed

upon bent 2 and 3.

This image

demonstrates a 3D model and how it would have a point

loading in the center. Upon inspection you will notice

that Bay 2, in-between bent 2 and 3 is the smallest. This

allows for there to be less of a moment or torque placed

upon bent 2 and 3.

- The Inspected Truss types

To the right, is an English Box

Truss. It is one of the more simplistic trusses that is used

in timber framing. There are variations where the timber

framer may curve all pieces with exception to the rafters

(the outside of the triangle) and the king post (the

vertical center piece). It is worth noting that this truss

is a right isosceles triangle. That means that each rafter

is the same length and this lends itself to the strength of

the triangle. Another common characteristic is that the

supporting members often connect in the middle of the

rafter. This is to ensure that the point load is directed

into the plate. The limitations of this truss is that you

must have a piece of timber that can span what ever length

is required to reach the breadth of the structure. Further,

the strength of the plate must be immense as it all

translates into the weakest point which is in the center of

the plate.

To the right, is an English Box

Truss. It is one of the more simplistic trusses that is used

in timber framing. There are variations where the timber

framer may curve all pieces with exception to the rafters

(the outside of the triangle) and the king post (the

vertical center piece). It is worth noting that this truss

is a right isosceles triangle. That means that each rafter

is the same length and this lends itself to the strength of

the triangle. Another common characteristic is that the

supporting members often connect in the middle of the

rafter. This is to ensure that the point load is directed

into the plate. The limitations of this truss is that you

must have a piece of timber that can span what ever length

is required to reach the breadth of the structure. Further,

the strength of the plate must be immense as it all

translates into the weakest point which is in the center of

the plate. This is an example

of a hammer beam truss. You may not recognize it right away

but it is seen in much of our famed architecture such as

Westminster hall and Annenberg hall. The Annenberg hall may

not sound as familiar but it is also known as the Harvard

freshmen dining hall and was used as the model for the

Hogwarts dining hall.

This is an example

of a hammer beam truss. You may not recognize it right away

but it is seen in much of our famed architecture such as

Westminster hall and Annenberg hall. The Annenberg hall may

not sound as familiar but it is also known as the Harvard

freshmen dining hall and was used as the model for the

Hogwarts dining hall.  Within this photo

there is striking beauty due to the lighting, the vaulted

ceiling, and the gorgeously woven wood and stone work. Where

the curve hammer beams are resting on the stone masonry

work.

Within this photo

there is striking beauty due to the lighting, the vaulted

ceiling, and the gorgeously woven wood and stone work. Where

the curve hammer beams are resting on the stone masonry

work.  This is a real photo of Annenberg Hall. It is much brighter,

as there are windows, the masonry is actually wooden walls

yet the magical-ness is still there due to the vast span of

the room and also the vaulted ceiling.

This is a real photo of Annenberg Hall. It is much brighter,

as there are windows, the masonry is actually wooden walls

yet the magical-ness is still there due to the vast span of

the room and also the vaulted ceiling. - Assumptions

This image

demonstrates a 3D model and how it would have a point

loading in the center. Upon inspection you will notice

that Bay 2, in-between bent 2 and 3 is the smallest. This

allows for there to be less of a moment or torque placed

upon bent 2 and 3.

This image

demonstrates a 3D model and how it would have a point

loading in the center. Upon inspection you will notice

that Bay 2, in-between bent 2 and 3 is the smallest. This

allows for there to be less of a moment or torque placed

upon bent 2 and 3.

- Assuming Snow weighs 7 lb per cubic foot. That is then 3.18 Kilograms per square foot and translates to 10.43 kilograms per square meter. Assuming that it snows in Fairbanks annually 5 feet per year or roughly 1.5 meters every truss system must be able to hold the weight of 15.65 Kilograms per square meter for snow.

- Another variable to consider is the weight of all roofing materials, and of course, the weight of the wood itself. The building materials we will consider are going to be the ceiling, tongue and grooved Douglas Fir lumber at roughly 2lbs per square foot at ½ inch thickness, 12 inches of sprayed foam at 1.5 lbs per cubic foot, slate shingles at 10lbs per square foot at ¼ inch thickness.

- The total weight per square foot of the prescribed thickness of the building materials is 13.5. That is 6.12 kg per foot which is roughly 20.1 kg/meter^2. We can round this down to 20kg/meter^2 Adding this to our snow weight which is 10.3kg /meter^2 This is roughly 30kg/m^2