Physics Of Trusses

- What is a truss?

- How is a truss assembled?

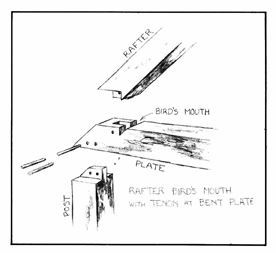

In modern building, thin members of wood two by fours are

placed within thin metal braces and nailed together.

This image demonstrates the utilitarian purpose

of this truss. They are spaced about 24 inches apart and

more than likely are sitting on a stud frame with each

stud 16 inches apart on center. This is known as stud

framing or balloon framing and became the standard of

building when quickness of production mattered over the

quality of the building.

In comparison

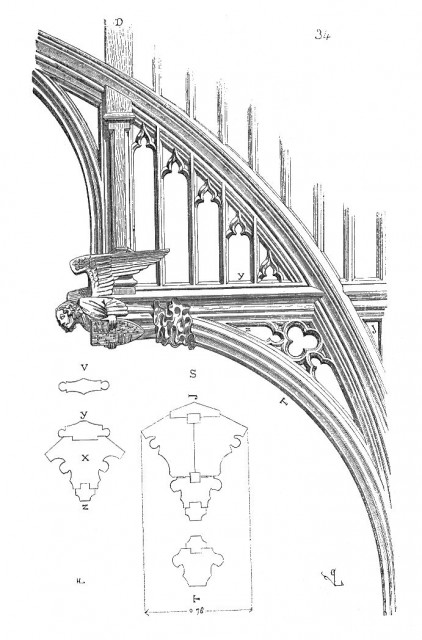

The image on the right

is of a segment of the hammer beam truss in Westminster hall. It

demonstrates how the embellishments were with what appears to be

thin keys that slid in between two pieces of carved wood and

held them together.

The image on the right

is of a segment of the hammer beam truss in Westminster hall. It

demonstrates how the embellishments were with what appears to be

thin keys that slid in between two pieces of carved wood and

held them together.

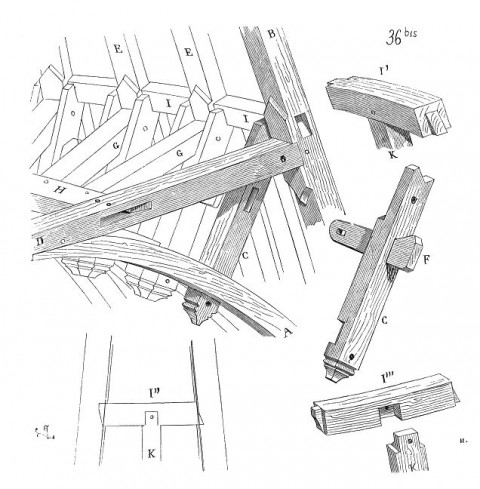

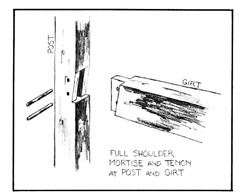

Here however, is how the pieces were actually assembled using

wooden pegs and many different pieces that latched together

and distributed their forces into the other member. To further

dissect this image and to more fully answer how trusses are

assembled within the scope of timber framing - in this image

there are different types of joints.

- A few different types of joints

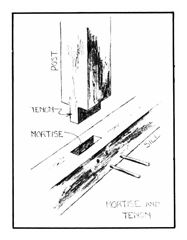

These are two variations of a mortise and tenon joint. These

are the most common joints in timber framing. The shouldered

mortise and tenon is different in that the downward force

isn't placed solely on the tenon, rather, it is also

transferred to the mortise beam. Another variation not

pictured is the housed mortise and tenon. The housed mortise

and tenon allows for the tenon beam to sit within the mortised

beam allowing for the forces to be distributed from all and to

all directions.