COMBUSTION

Combustion occurs in diesel engines. As the

piston moves up and down in the cylinder, there is fuel

sprayed in at high pressures while the piston also creates

high-pressure air. When the fuel and air combust at the top of

the combustion chamber, a lot of Thermal energy is

released and forces the piston down. This cycle is repeated

over and over. This is what makes the crankshaft spin and give

the engine its rpm (Rotations per Minute). Thermal

energy is then converted into Mechanical energy as

the crankshaft is turned. Once again the torque of the pistons

will be rotating the crankshaft. This is the energy that will

eventually turn the flywheel, which can be hooked up for use

for movement, generation, and other uses.

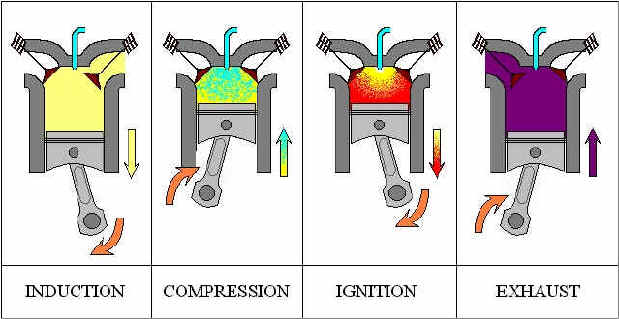

The 4 steps of

combustion are shown below:

Intake- air is drawn into to cylinder by a down stroke of

the piston and the intake valve opening

Compression - the intake and exhaust valve are closed

as the piston compresses the air in the cylinder in an up

stroke, atomized fuel is also injected in

Combustion - the atomized fuel, and hot air are at a

very high pressure, causing them to ignite. This created a

small explosion which forces the piston back down

Exhaust-the exhaust valve opens letting the exhaust out

as the piston begins to start its up stroke, and the cycle

repeats over and over!

The bearings and bushing surround the rotating parts to reduce

Friction on the

rotating parts. This reduces wear on the interal parts of the

engine and lets more energy transfer from part-to-part. If

energy is not lost to friction, then more energy is

transferred into the cycle, therefore more output power is

created and efficiency goes up.

Efficiency is very important for fuel mileage

and engine performance !

Efficiency can be simply equated as (Power in) / ( Power out )

The more ouput power, the higher the efficiency.