DESIGN ISSUES

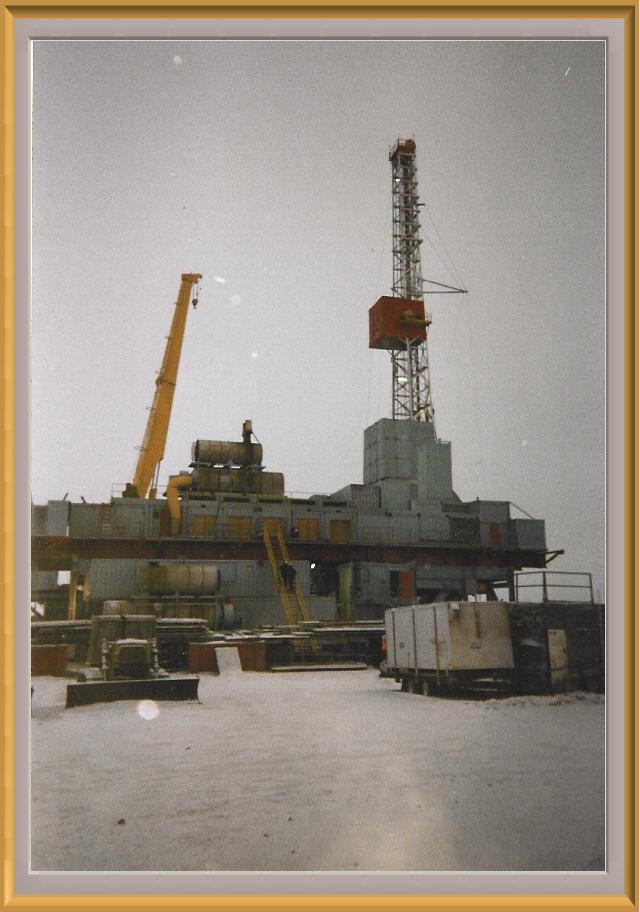

There are many things to consider when constructing a drilling platform. To get an understanding of just how big these systems can be, a picture is worth a thousand words. This rig, constructed in 1997 by Pool Arctic of Alaska inc., stands 175 feet tall and weighs ove 1 million pounds fully asseembled. The derrick telescopes and uses hydraulic rams to stand it up. It is a modular system that is designed to meet the demands of its operating environment. It can be assembled by a crew of about 20 persons in just a few days. It can also be moved as a unit with a large capacity "sow". This section, along with a pipe handling section, a mud module and a living quarters module comprise this workover rig configuration. This particular rig is still in use on the North Slope of Alaska, now known as Nabors inc. rig 19. The physics involved in this design are incredible. Cranes, pulleys, electrical systems, piping systems, heat exchangers, rotary tables, traction motors, hydraulic systems and more.