|

|

There have been many

types of gunpowder throughout history,

starting with the classic black powder

and ending with the modern smokeless

powder, which avoids many of the

problems that could occur from using other

powders. Some of these problems included

fouling up the firearm, burning too quickly

and causing an explosion, and hazardous

manufacturing requirements.

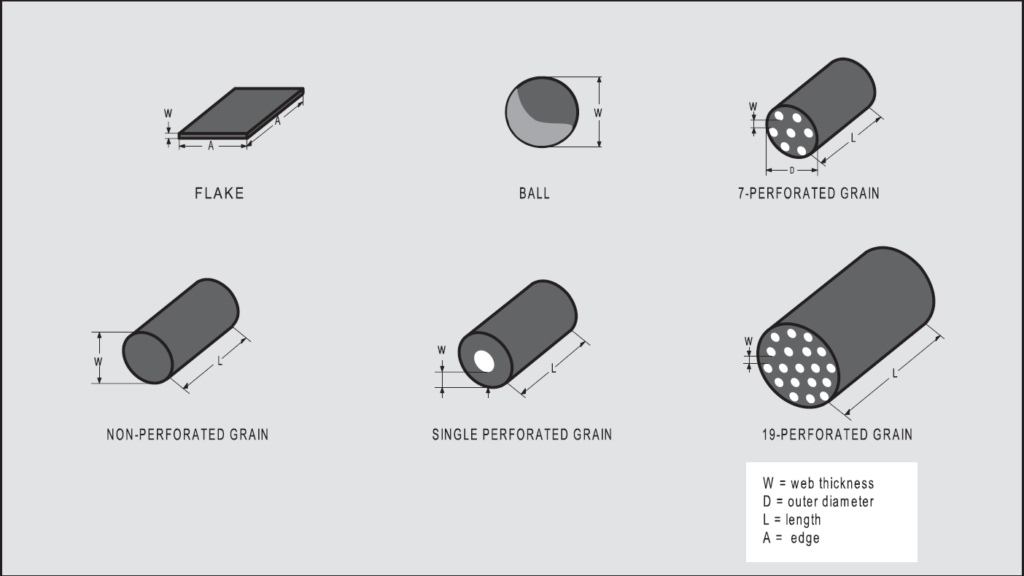

It can also be important

to know the shape of the powder grain,

how it effects combustion, and how easily it

can be measured out (or metered).

Flake Powder:

Usually used in shotgun rounds, this grain

shape can be difficult to predict as it

can end up stacking when being measured

out and be less uniform in the bullet

casing.

|

Ball Powder: Most commonly

used in automatic firearm rounds, this grain

is relatively inexpensive to manufacture and

is easy to accurately meter and can settle

uniformly in the casing.

Stick Powders: This cylindrical grain

is most popular for rifle rounds but is the

most difficult to meter properly. These can

also break while measuring, leading to

inconsistencies in the powder.

Multi-perforated Grains: These

stick powders are designed with a number of

holes going from one end to the other in

order to increase the surface area,

increasing the speed of combustion. The more

perforations the grain has, the larger the

grain is. These types of powders are usually

used for large caliber ammunition.

|

From: https://www.vihtavuori.com/tech-blog-powder-grain-shapes/

|