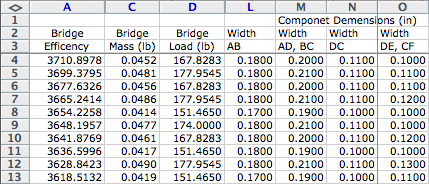

Seeing how the maximum loads of the parts of the bridge are a function of the cross-sectional area of said parts, using a spreadsheet will make data organization simple. The widths of the materials are 0.185", 0.125", 0.095", and 0.065", resulting in 256 combinations of bridge designs. With this list of all possible configurations, we can calculate the strength, mass and efficiency of each design. Below are the fourteen most efficient member size combinations.  The load column is calculated considering the weakest part of the truss system from the equations at the bottom of the Analysis page. Efficiency is defined as the mass of the bridge (mbridge) divided by the maximum load of the bridge (Lbridge).

The load column is calculated considering the weakest part of the truss system from the equations at the bottom of the Analysis page. Efficiency is defined as the mass of the bridge (mbridge) divided by the maximum load of the bridge (Lbridge).

Pulling from past experience with building these kind of bridges, the first three configurations lead to issues with stability due to member flex. Following this, the fourth row's values have been chosen to be built and tested, which are highlighted.

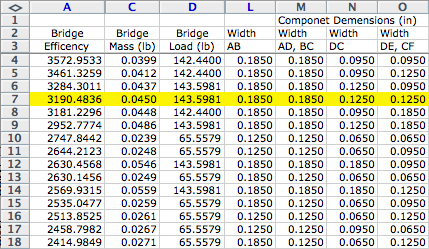

As a side note, only the four different sizes of material were used because it is what was on hand to build and test bridge with. However, creating a spreadsheet for member sizes between 0.01" and 0.25" in increments of 0.01", the following values apply. This spreadsheet ended up having 406,000 rows, but here are the top ten values.