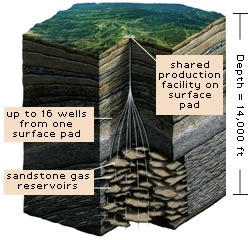

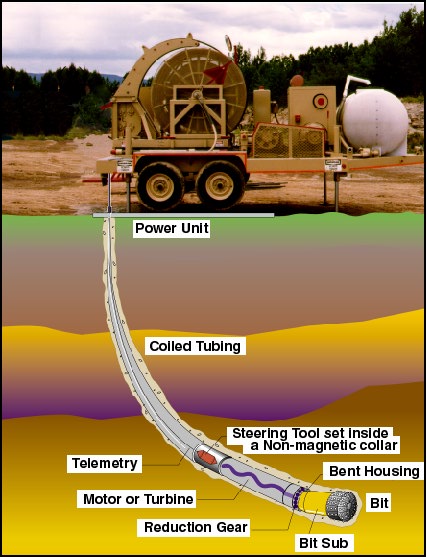

Coiled tube drilling (CTD) has been around for several years and has been a huge asset to the oil industry for many reasons, including cost advantages. It allows safe and efficient pressure control during the drilling process and unlike the conventional method of numerous amounts of drill pipe, CTD ensures faster tripping time (the time needed to change a drill bit or run a log in the well bore). It also ensures needing less personnel to get the job done. In the traditional method the drill pipe is typically 30 feet in length and three sections are jointed together. To change a bit that has worn or broken, several derrickmen must pull out each drill stand of 90 feet in length and store them to allow for the bit change or an open hole procedure. This may happen several times during the drilling process and can take many hours do to so depending on the depth. The depth can range from a few thousand up to approximately 20,000 feet!

You can imagine how long one trip would take to remove 10,000 feet of drill pipe and then put it back. However, the CT unit operator can do this from the control cabin. Also with CTD there is no need for a huge derrick or mast. The derrick and mast are used as a support structure and a place to store all the drill pipe, producing a much smaller footprint and much less weight. Time is money, so the fact that it is much quicker to rig the unit up and down than the traditional drilling method is a huge benefit for the oil companies.