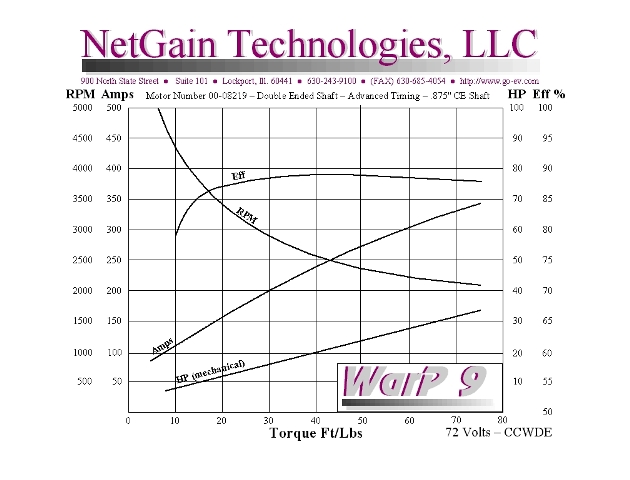

For the most part, electric conversion vehicles use series DC motors. My motor is a series DC motor. You can use recycled motors from electric forklifts and other machinery. However, there are two manufacturers that produce motors specifically for electric vehicles. I required a 9” diameter motor because my vehicle weighed over 4000 pounds. Either I was going to purchase an Advanced DC motor or a NetGain WarP motor. I went with the WarP; although both were priced at about $1500, it promised a higher efficiency. Even though electric motors convert the Power (Amps * Volts) directly into motion with little loss, you can still lose about 20% due to heat and friction. The WarP promised a higher efficiency closer to 90%.

Motor efficiency decreases in several areas: copper losses, iron losses, friction and windage, and constant losses. Even with all those failings, the motors do pretty well compared to a gasoline engine. A motor could be made 25% lighter, but its efficiency will suffer.

Other motors can be used in electric vehicles including AC, 3 phase AC, and permanent magnet DC. The series DC motor is the simplest motor to use. An AC motor would require a higher voltage and an inverter for the DC batteries to power an AC motor. This adds cost, and complexity.

My next electric car, a 1998 Chevy Metro:

Here is the manual transmission (left) and a shunt DC motor that will be mounted together: