Physics Behind Modern 4 Stroke Engines

David Giessel

University of Alaska Fairbanks

Physics 211 Web Project, Fall 2002

David Giessel

University of Alaska Fairbanks

Physics 211 Web Project, Fall 2002

| Index | Engine Basics | Horsepower vs Torque | More Power via Boost | Bibliography | |

When looking for more power one must first understand where power comes from...burning gasoline. You can't make power unless you burn more gas. There are only so many BTUs/liter (or gallon) for any fuel source and once you have an efficient way to extract them the only way to get more output is to burn a larger volume. To burn more gas with the correct mixture of fuel and air however, more air is needed. This brings us to the topic of Boost. Now a lot of V8 guys talk about "headers" and "carbs" when they discuss more power. This is because these parts of the engine when modified allow a greater volume of air to flow in and out for each combustion cycle. Doing "breather" mods like this to a "normally aspirated" engine (an engine that breathes air at atmospheric pressure) will allow gains in power to an extent, but an engine can only suck in so much air on its own. The term "boost" refers to positive pressure. More specifically it refers to positive air pressure in the intake manifold. The idea is to force feed the engine air at a pressure greater than atmospheric pressure in order to burn a LOT more fuel. There are 3 ways to achieve this goal: Nitrous Oxide injection, Supercharging, and Turbocharging.

Nitrous Oxide

Nitrous Oxide kit from Nitrous Express

Nitrous Oxide or N2O adds power in two ways. Firstly, nitrous is 33 percent oxygen by volume. In contrast the air we breathe is only 21 percent oxygen. So injecting a shot of N2O into the intake charge of air increases the percentage of oxygen that is entering the cylinder. Secondly, nitrous is injected from a pressurized bottle. As gasses are taken from high pressure to a lower pressure their volume increases and their temperature drops. When nitrous leaves the injector nozzle it is typically below 0 degrees Centigrade. Lower air temperatures yield another benefit for an engine, greater mass of air. As air cools it becomes more dense so a greater mass can fit into the same space. So when nitrous is injected, the percentage of oxygen in the intake air stream increases, AND, the amount of air entering the cylinder also increases due to the colder intake air temps. While nitrous does not produce positive intake manifold pressure, it does cram more oxygen into the cylinder and is therefore considered a form of boost.

Supercharging

Eaton M45 Blower from Eaton Automotive

Supercharging is one of the simplest and most common forms of boost available. Superchargers are used in production cars such as the Ford Mustang SVT, Supercharged Buicks, and the Pontiac Grand Prix GTP. Roots style superchargers use a belt driven blower to stack layers of air in the intake manifold producing positive manifold pressure. These are by far the most common type of superchargers and they are seen on production 6 cylinder cars all the way up to 6 second dragsters. Another type of supercharger is the centerfugal supercharger. Centrifugal superchargers have a belt driven turbine that pressurizes air and channels it into an outlet that is then routed to the intake manifold. Both types produce similar output and generate similar horsepower numbers. The main disadvantage of a supercharger is that after it can only compress the air. Unlike nitrous oxide, it does not cool the intake charge. In fact it heats it up (as air is compressed its temperature increases). This means that although higher pressure air is being pushed into the engine some power is being lost to to the air being less dense. Generally this is an accepted loss in supercharged cars and this small inefficiency is overlooked.

Turbocharging

Twistec manifold and Turbo forom Twistecproducts.com

Turbocharging is by far the most efficient way to get more power out of an engine. Turbochargers compress air using a turbine much like a centerfugal supercharger, however they are not driven by a belt. Instead they are driven by exhaust gasses leaving the engine (using waste energy to make more power).

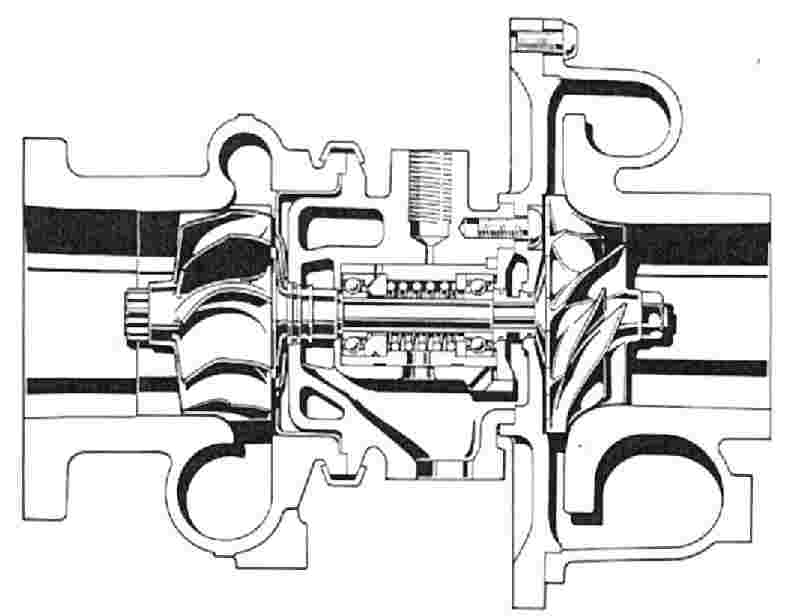

Turbocharger cutaway picture

A turbocharger contains two turbines connected by a central shaft. In the picture above the intake turbine is on the left and the exhaust turbine is on the right. What happens when a turbo "spools" or spins up is a "wastegate" (exhaust bypass allowing the engine to operate without sending exhaust gas through the turbo) closes sending exhaust into the exhaust housing of the turbo. The gasses spin around this housing until they are channeled into the center where the exhaust turbine is. As the gasses pas this turbine they spin it up causing the shaft through the turbo and the intake turbine to spin at the same speed. The exhaust gasses exit the housing into the exhaust pipe and are done with, but on the other end of the turbo the real fun is going on. As the turbines spin up the intake turbine begins to suck air in and push it into the compressor housing. From here it is sent out into the intake tube at high pressure.

intake turbine

exhaust turbine

As we know from the supercharger, this compressed air is hot. However, with a turbocharger, we have the option of cooling this air with an "intercooler." An intercooler can be one of two types: Air/Air (more common) or Air/Water (used on dragsters). An Air/Air intercooler passes air through channels separated by small gaps. These gaps are filled with a zig zag of aluminum fins much like a car radiator. As the hot air passes through the intercooler passages cold air passes through it perpendicular to the sealed path of the compressed air. This allows a cold yet pressurized charge of air to exit the intercooler and go into the engine.

Massive IC from Gary Donovan's 10 second Reliant K at The Dodge Garage

Fuel Management

When boosting (or adding any significant amount of air to the cylinders) it is important to keep a air fuel mixture that is close to 14.7:1. If you go "lean" under boost exhaust gas temperatures will skyrocket above 2000 F resulting in burnt valves, collapsed pistons, and smoked bearings. It is important to remember that power does not come from nitrous or boost, it comes from burning more fuel in the same amount of time. Another thing to look out for when boosting or running higher compression is detonation. Detonation occurs when the air fuel mix is under such high pressure (due to having air forced into the cylinder or just higher compression) that it explodes spontaneously before the piston reaches TDC. This results in the piston being driven backwards and destroys an engine in a fraction of a second. Higher octane fuels were developed to prevent detonation as they are less volatile. These fuels when burned in a regular engine (compression ratios between 9:1 and 9.5:1) will not burn completely resulting in excess carbon buildup (this is why you SHOULD NOT use anything higher than 87 octane in a regular engine). However, in a high compression engine as are seen in high end sedans and coupes these fuels will prevent detonation and yield better power and reliability. The octane rating is the only difference between fuel grades at the gas pump so don't be fooled into thinking that "premium" gas is any cleaner or that it will make your car run any better, it will only burn differently.

Conclusion

With adequate fuel supply and boost in some form (Nitrous, Supercharger, or Turbo) it is possible to greatly increase output without having to increase the RPM range or displacement of an engine. Power levels as high as 300-400 HP can be extracted from 1.8-2.2L engines with properly designed and managed boost setups.