img src: https://powergen.gepower.com/plan-build/products/gas-turbines/index.html

img src: http://sounak4u.weebly.com/vapour--combined-power-cycle.html

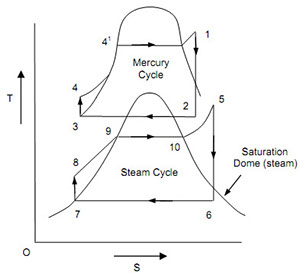

The T-S diagram above shows how the two cycles complement each other. The bell shaped curve is the vapor curve for water. Gas-Turbine cycles typically operate at considerably higher temperatures than steam cycles. The maximum fluid temperature at the turbine inlet is about 620C (1150F) for modern steam plants, but over 1425C (2600F) for gas-turbine plants. By combining the two cycles, energy is recovered from the exhaust gases by transferring it to steam in a heat exchanger that acts like a boiler.

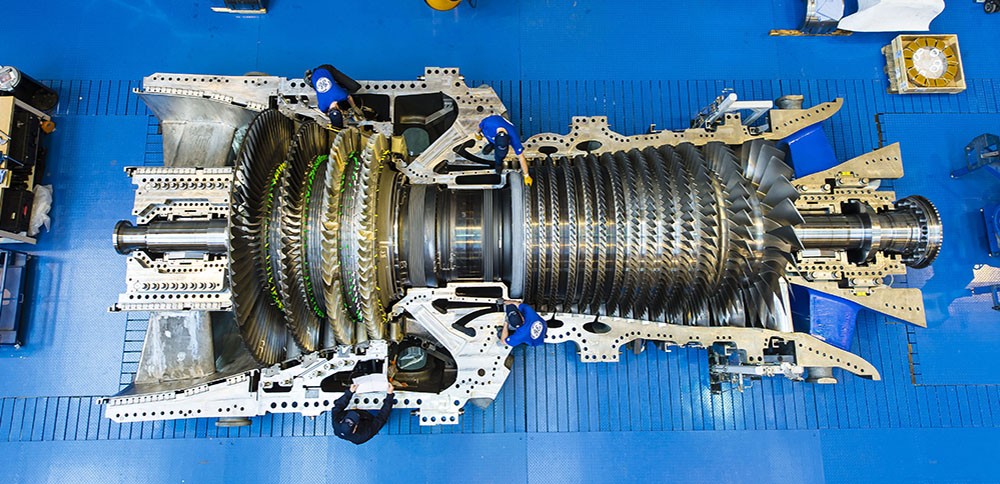

Developments in gas-turbine technology has made the combined gas-vapor cycle very attractive economically. Efficiency is increased without much more investment monetarily. New ceramics and engineering advances have been able to increase the temperatures at which heat is supplied, increasing thermal potential for gas power plants.

Another topic of interest when combining cycles is a for special applications. Even though water is the most prominent working fluid, because it is readily available, it isn't the only one. When looking at Binary Vapor cycles, it is possible to top a steam Rankine Cycle with a another Rankine cycle that has a vapor curve that occurs at a much higher temper.

Referring to the T-S diagram below, you can see how the mercury vapor curve lies above the water vapor curve. The cycle operates in a similiar way to the gas-vapor cycle by using a heat exchanger to condense the mercury, and to act as a boiler for the steam.

In the real world, these events don't happen isentropically, but engineers try to find a way to become as close to isentropic as possible by implementing other stages in the cycle to improve its efficiency.

Why use combined cycle power plants?

img src: http://www.expertsmind.com/topic/vapor-power-cycles/binary-vapor-cycle-97686.aspx