INTRODUCTION

Wind machines were used for grinding grain in Persia as early as 200 B.C. This type of machine was introduced into the Roman Empire by 250 A.D. By the 14th century Dutch windmills were in use to drain areas of the Rhine River delta. In Denmark by 1900 there were about 2500 windmills for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 MW. The first windmill for electricity production was built in Cleveland, Ohio by Charles F Brush in 1888, and in 1908 there were 72 wind-driven electric generators from 5 kW to 25 kW. The largest machines were on 24 m (79 ft) towers with four-bladed 23 m (75 ft) diameter rotors. Around the time of World War I, American windmill makers were producing 100,000 farm windmills each year, most for water-pumping (MacCormack J., 2007). By the 1930s windmills for electricity were common on farms, mostly in the United States where distribution systems had not yet been installed. In this period, high-tensile steel was cheap, and windmills were placed atop prefabricated open steel lattice towers.

A forerunner of modern horizontal-axis wind generators was in service at Yalta, USSR in 1931. This was a 100 kW generator on a 30 m (100 ft) tower, connected to the local 6.3 kV distribution system. It was reported to have an annual capacity factor of 32 per cent, not much different from current wind machines. The very first electricity generating windmill operated in the UK was a battery charging machine installed in 1887 by James Blyth in Scotland. The first utility grid-connected wind turbine operated in the UK was built by the John Brown Company in 1954 in the Orkney Islands. It had an 18 meter diameter, three-bladed rotor and a rated output of 100 kW.The first use of a large windmill to generate electricity was a system built in Cleveland, Ohio, in 1888 by Charles F. Brush. The Brush machine (shown in Figure 3) was a postmill with a multiple-bladed "picket-fence" rotor 17 meters in diameter, featuring a large tail hinged to turn the rotor out of the wind. It was the first windmill to incorporate a step-up gearbox (with a ratio of 50:1) in order to turn a direct current generator at its required operational speed (in this case, 500 RPM.)

Despite its relative success in operating for 20 years, the Brush windmill demonstrated the limitations of the low-speed, high-solidity rotor for electricity production applications. The 12 kilowatts produced by its 17-meter rotor pales beside the 70-100 kilowatts produced by a comparably-sized, modern, lift-type rotor.

In 1891, the Dane Poul La Cour developed the first electrical output wind machine to incorporate the aerodynamic design principles (low-solidity, four-bladed rotors incorporating primitive airfoil shapes) used in the best European tower mills. The higher speed of the La Cour rotor made these mills quite practical for electricity generation. By the close of World War I, the use of 25 kilowatt electrical output machines had spread throughout Denmark, but cheaper and larger fossil-fuel steam plants soon put the operators of these mills out of business. By 1920, the two dominant rotor configurations (fan-type and sail) had both been tried and found to be inadequate for generating appreciable amounts of electricity. The further development of wind generator electrical systems in the United States was inspired by the design of airplane propellers and (later) monoplane wings.

Figure 2: The World's First Megawatt Wind Turbine at Castleton, Vermont

(Courtesy: U.S Department of Energy)

Figure 3: The Brush Post mill in Cleveland, Ohio, 1888 (Dodge, G.M. 2007)

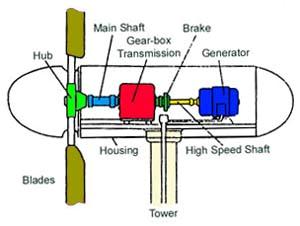

Figure 4: Internal Mechanism of a Wind Turbine

(Courtesy: http://www.energyquest.ca.gov/story/chapter16.html)