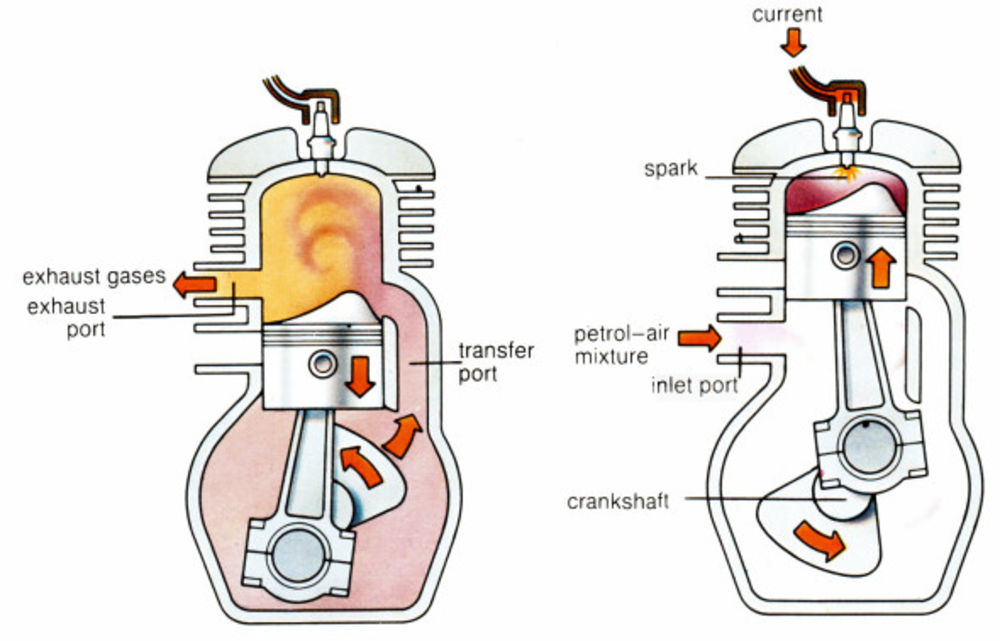

Stage One: Upstroke

The crankcase of the engine contains a one-way valve that allows the fuel/air mixture to enter. As the piston rises during the upward stroke, it creates a vacuum by increasing the volume of the crankcase. Based on the ideal gas law, PV=nRT, to balance out this increase in volume, a decrease in pressure is needed, thus a vacuum is drawn. This vacuum forces the intake valve open and sucks the fuel/air mixture into the crankcase. There is a transfer port between the crankcase and the combustion chamber, but during the upstroke this port is closed. As the fuel/air mixture is being sucked into the crankcase, the fuel/air mixture already in the combustion chamber is being rapidly compressed. The rapid increase in pressure raises the temperature of the mixture by adiabatic heating, and when the piston reaches the top of its stroke, the spark plug fires, igniting the fuel/air mixture and initiating the next stage.Without the adiabatic heating, the spark from the spark plug would be insufficient to ignite the gasses.

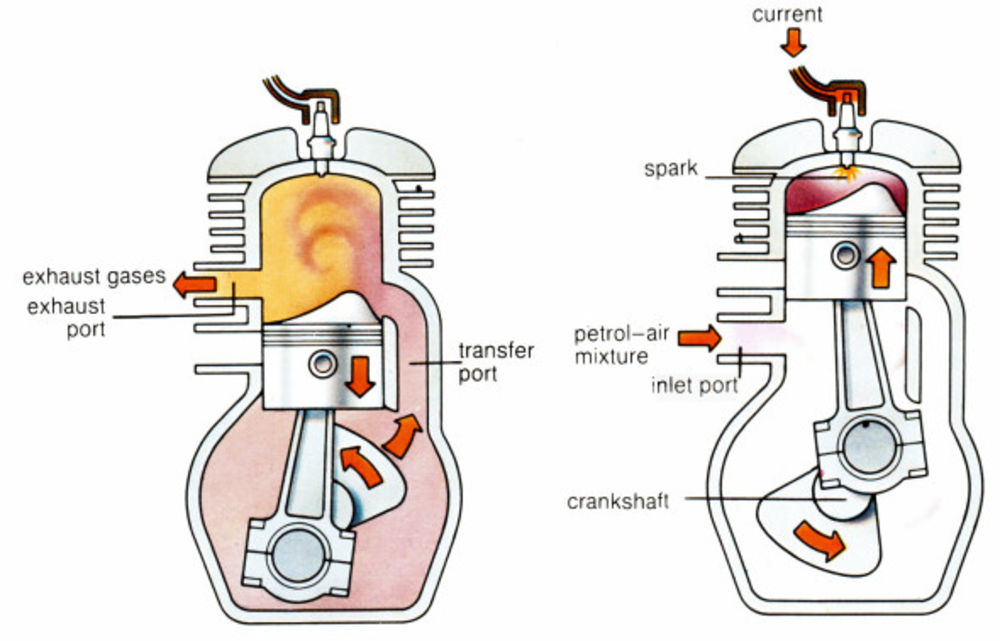

Stage Two: Downstroke

The ignition of the fuel/air mixture in the combustion port creates a massive increase in pressure which rapidly forces the piston into the downstroke. During the downstroke, both the transfer and exhaust ports are exposed. The downward motion of the piston compresses the crankcase, which forces the intake valve shut and increases the pressure of the fuel/air mixture trapped within the crankcase. When the transfer port is opened, the mixture in the crankcase is forced into the combustion chamber which in turn forces the exhaust gasses out via the exhaust port. When the piston reaches the bottom of its stroke, it transitions upward again, closing off the transfer and exhaust ports and beginning the cycle all over again.

Home Page

Drive System

Cooling System

Chassis

Riding Technique

Bibliography

The crankcase of the engine contains a one-way valve that allows the fuel/air mixture to enter. As the piston rises during the upward stroke, it creates a vacuum by increasing the volume of the crankcase. Based on the ideal gas law, PV=nRT, to balance out this increase in volume, a decrease in pressure is needed, thus a vacuum is drawn. This vacuum forces the intake valve open and sucks the fuel/air mixture into the crankcase. There is a transfer port between the crankcase and the combustion chamber, but during the upstroke this port is closed. As the fuel/air mixture is being sucked into the crankcase, the fuel/air mixture already in the combustion chamber is being rapidly compressed. The rapid increase in pressure raises the temperature of the mixture by adiabatic heating, and when the piston reaches the top of its stroke, the spark plug fires, igniting the fuel/air mixture and initiating the next stage.Without the adiabatic heating, the spark from the spark plug would be insufficient to ignite the gasses.

Stage Two: Downstroke

The ignition of the fuel/air mixture in the combustion port creates a massive increase in pressure which rapidly forces the piston into the downstroke. During the downstroke, both the transfer and exhaust ports are exposed. The downward motion of the piston compresses the crankcase, which forces the intake valve shut and increases the pressure of the fuel/air mixture trapped within the crankcase. When the transfer port is opened, the mixture in the crankcase is forced into the combustion chamber which in turn forces the exhaust gasses out via the exhaust port. When the piston reaches the bottom of its stroke, it transitions upward again, closing off the transfer and exhaust ports and beginning the cycle all over again.

Home Page

Drive System

Cooling System

Chassis

Riding Technique

Bibliography