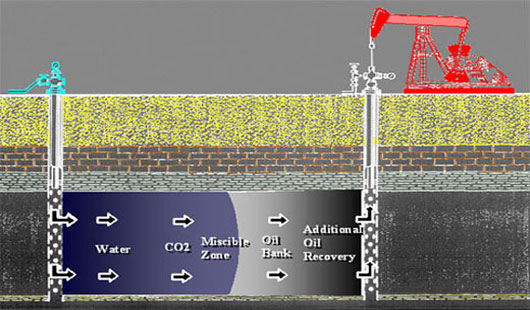

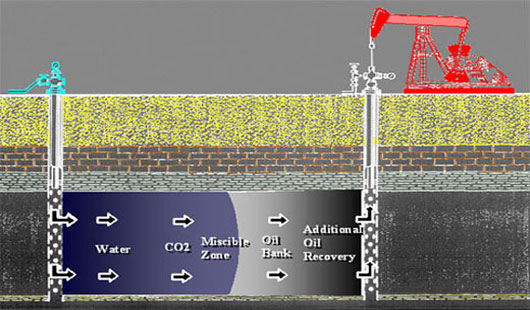

Miscible gas injection differs from basic gas

injection in that the components of the produced gas are altered

to allow the gas to combine with the residual oil in a

reservoir. The gases typically used in miscible gas injection

are CO2, nitrogen, and hydrocarbon gases such as propane and

butane. The miscibility of a gas with oil depends on the

temperature and pressure of its environment. Gas must be dense

enough for it to be soluble with oil, so the high pressure of

oil reservoirs is ideal for this recovery technique.

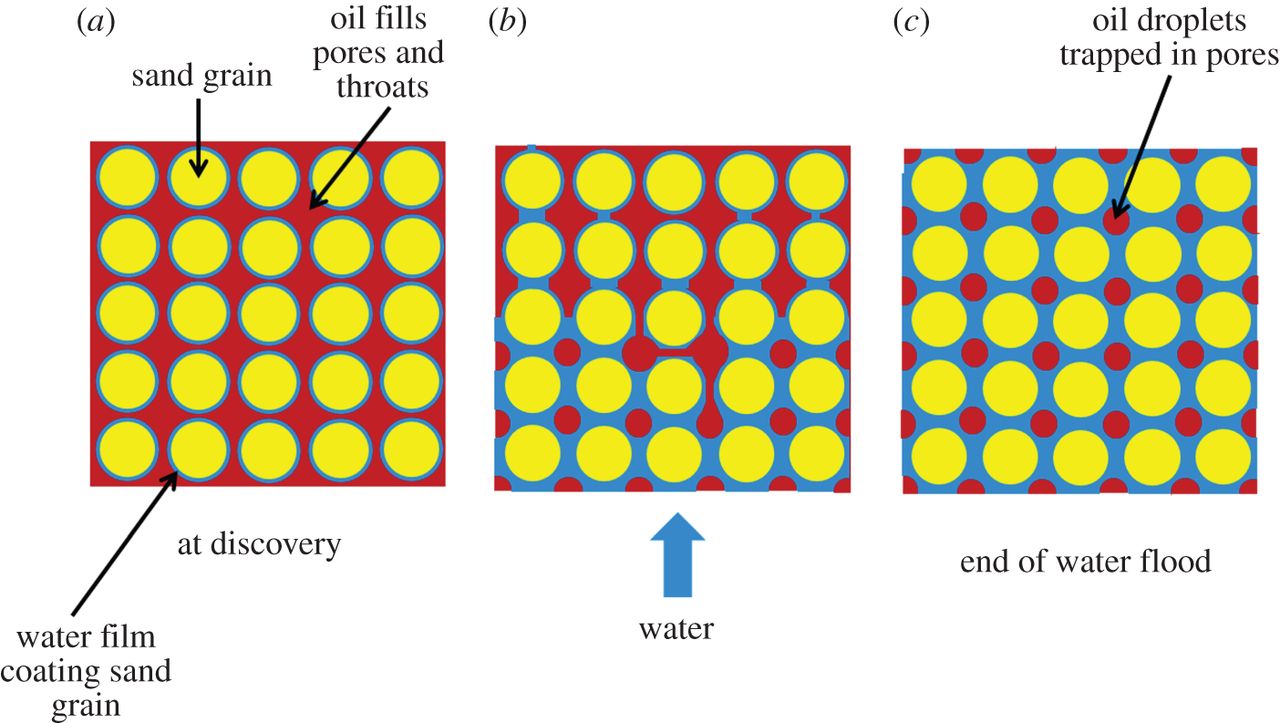

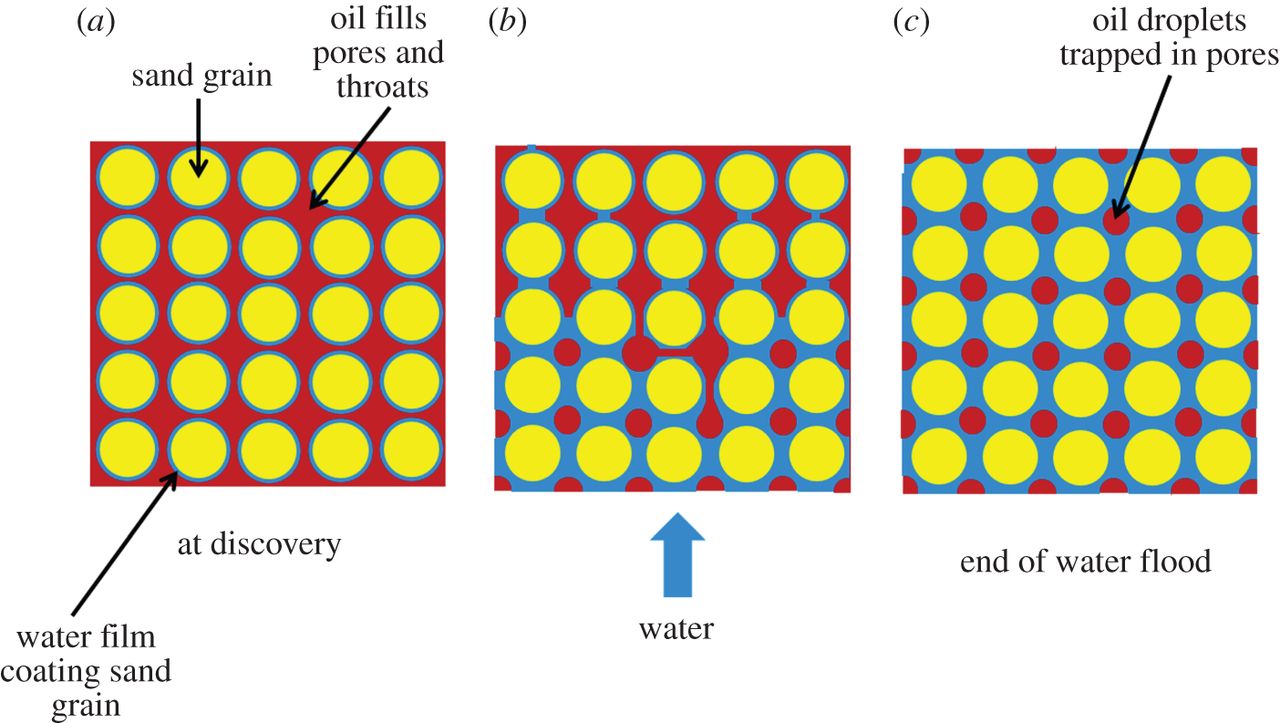

Miscible gas injection affects a factor of recovery called pore

scale displacement, which means how much oil in a pore is

produced. When a reservoir has been through waterflooding, the

oil in the pores may lose flow continuity and become trapped in

water.

http://rsta.royalsocietypublishing.org/content/372/2006/20120320

http://rsta.royalsocietypublishing.org/content/372/2006/20120320

Since oil is not miscible in water and water has developed

a flow path, further water flooding will cause water to flow

past the oil and the reservoir will produce the injected water.

So, in miscible gas injection, The injected gas enters the pores

and begins to mix with the oil until there is one substance in

the affected part of the reservoir. Since oil is no longer

trapped in the pore, but rather dispersed through the gas, the

oil can move with the gas in a continuous flow towards the well.

http://www.co2.no/default.asp?uid=53&CID=24

http://www.co2.no/default.asp?uid=53&CID=24