Methods of

Construction: Ramps

Once the blocks were on

site, they would have to be lifted to their final

resting place, often hundreds of feet up. Without access

to modern construction techniques to lift the blocks

straight up, the Egyptians were left to innovate some

simple but clever tools to get the blocks to their final

resting locations. One such tool they likely used was a

ramp. A ramp is

an inclined plane, a type of simple machine which

decreases the amount of force needed to lift an object

by increasing the distance that it must travel.

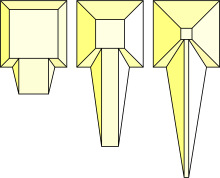

Straight Ramps:

(Image Credit: commons.wikimedia.org)

- It would allow for multiple work teams to traverse it at a time

- The gradient

of the ramp could be easily customized and

optimized by changing the length of the ramp

- It could

provide a straight path for the blocks to be

dragged up, free of any sharp turns that the

blocks must be maneuvered around

However, once the

pyramid reached a certain height this design would

have become infeasible. With a reasonable gradient of 1 in 10

for dragging the blocks up the slope, a straight

ramp would have been an incredible construction

project in and of itself. With some calculations

indicating that it would have had a volume greater

than the pyramid itself in order to reach the top,

making it impractical extending to this height

4.

Spiral Ramps:

One of the most widely accepted ramp design among Egyptologists is a spiral ramp 5. This design overcomes many of the problems with the straight ramp. It could be built into the side of the pyramid itself and thus would not require an additional massive construction project. It could also progress easily with the construction of the pyramid to much greater heights.

But even this design is not without its flaws. A spiral ramp could only be so wide, it would be constrained by the geometry of the pyramid itself. And this constraint presents several disadvantages:

- A narrow ramp cannot allow for multiple teams to be on the ramp at once

- The tight, right hand corners of the pyramid would force the blocks to be adjusted at each corner before the work teams could continue carrying it up the pyramid