Early Clock Designs

1717 long case clock, one of the earliest built by Harrison http://www.nationaltrustcollections.org.uk/object/959830 |

Harrison's earliest clock designs were primarily pendulum clocks that he would design and then build, often with the help of his brother James. In 1722, Harrison completed a turret clock that needed no oiling by using a type of self-greasing wood called lignum vitae. He also used newer oak wood (which is stronger and heavier than older oak) for the teeth of the gear wheels, and he used older oak for the center of the gears, to keep the parts somewhat lightweight. The clock is still in operation to this day and has been continuously wound every week, except for a brief refurbishing in 1884. One benefit of not having to oil a clock, is that when the lubricant used in the clock is subjected to different temperatures, it will have different viscosities. Thus, in hotter weather, most 18th century clocks ran slower, while cold weather would cause the clocks to run faster. |

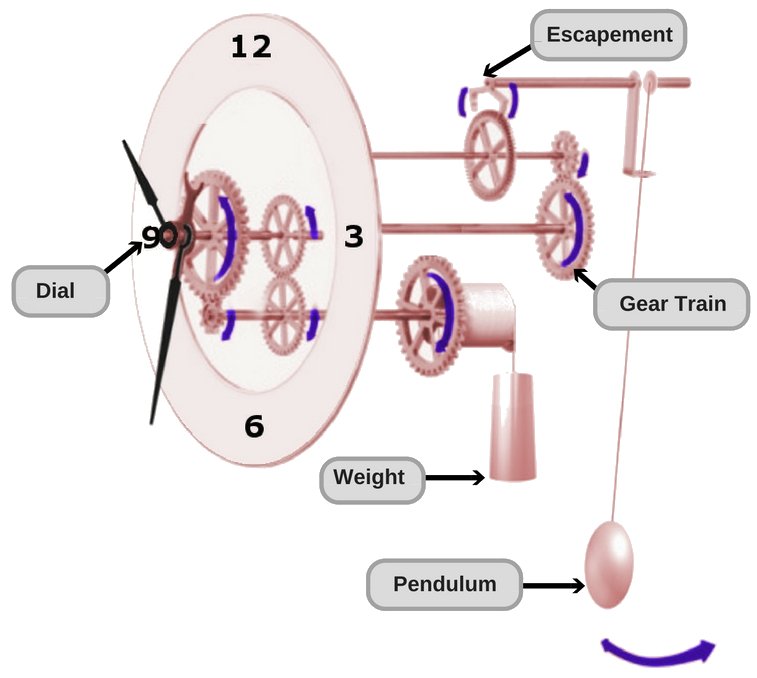

The Inner Workings of a Pendulum Clock https://www.scienceabc.com/innovation/pendulum-clock-works-escapement-ticking-sound-falling-weight.html |

A Moving Pendulum https://www.scienceabc.com/wp-content/uploads/2016/08/working-of-a-pendulum-clock.gif So, how exactly does a pendulum clock work? A pendulum is attached to an escapement, and each time the pendulum completes a swing, the escapement mechanism will move a notch. The pendulum converts between kinetic and potential energy as it swings. The length of the pendulum will also dictate how quickly the escapement wheel turns. For example, a 1 meter long pendulum should turn the wheel every second. The escape wheel is attached to the gear train and will move the other gears accordingly. The minute hand will be set up at a 1/60th ratio compared to the second hand, and the hour hand will be set up at a 1/60th ratio compared to the minute hand. A weight will be attached to a gear, which will give the gears the power to turn automatically. When the weight finally falls to the ground, the clock will need to be rewound. The escape mechanism keeps the weight from freely falling. |

Moving Diagram of a Grasshopper Escapement https://upload.wikimedia.org/wikipedia/commons/7/7b/Grasshopper-escapement_colored.gif |

The grasshopper escapement was a breakthrough in clockmaking. Most escape mechanisms of the time involved sliding friction between the escape mechanism and the gear. Because of the sliding friction, many escape wheels required periodic oiling, or else the clock would eventually become incredibly inaccurate. Harrison strove for accuracy, and made an escape mechanism that required no lubrication. The mechanism actually gently pushes the arms out of place, eliminating sliding friction. The only problem with the grasshopper mechanism, was that it was very fragile. Even so, Harrison used the grasshopper mechanism in his first three marine chronometers. |

previous home forward