introduction

Tension Control (TC) bolts are a unique type of bolt assembly that aredesigned for ease of installation and inspection.

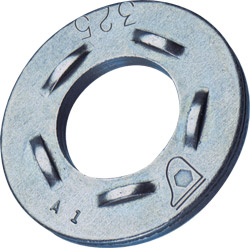

Lets first look at the standard Hex Bolt

(Shown on the right)

A regular hex head bolts that requires a direct tension indicator washer (DTI) to determine if it has reached the correct tension. A DTI is a washer with bumps on it, as the tension increases these bumps begin to flatten out and to find it they are at the correct tension one must use a feeler gauge to determine how much they have been flattened which can be very time consuming when there are thousands of bolts to check.

Now lets compare this painstaking process to tension control bolts.

(shown on the right)

A tension control bolt has a section of

the bolt called the spline, the spline has a shear plane

between it and the rest of the bolt which allows it to

snap off when the correct tension is achieved. As long as

the bolts are manufactured properly and comply with very

specific codes then the spline will snap off at or just

above the minimum required tension on all of the bolts.

The great part about this is that instead of having to

meticulously check each DTI washer one can simply glance

at a bolt and visually see from a distance that the spline

has been snapped off and therefore it has reached the

proper tension. The specifications of these bolts helps

regulate proper manufacturing, installation, and

inspection; however itís the physics behind these bolts

that is intriguing and allows them to function properly.