Components

It is often said that a torque converter is the most complicated component in a vehicle. Using fluid to connect the engine to the rest of the drivetrain isn't necessarily a logical solution, but once one understands how these devices work, it makes much more since.

|

|

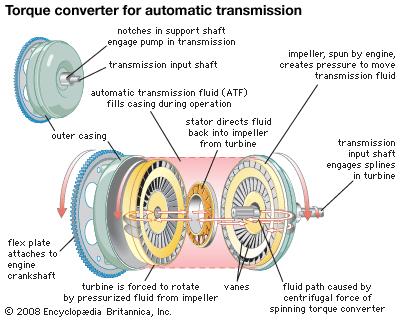

HousingThe torque converter housing is typically made of steel. A splined or keyed output shaft sticks out of one end and connects with the transmission. Transmission fluid flows through the opening within the shaft to allow new fluid to enter and old fluid to exit and cool. The other end of the housing bolts to the flex plate on the rear of the motor, which rotates with the engine's crankshaft. The output shaft spins independent of the housing, as the housing and shaft typically rotate at different speeds.

Impeller

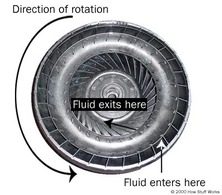

The impeller, also called the pump, is responsible for transferring the energy from the engine into the transmission oil, which the torque converter is completely full of. The impeller is attached to the housing and rotates with it, 1:1. As shown in the image to the left, as the impeller spins, fluid is taken in at its center and is pushed outwards through the fins. For an explanation as to why this occurs, click here. As the fluid exits the fins along the outside walls of the torque converter, it is pushed toward the turbine.

TurbineThe turbine is attached to the output shaft, and is responsible for taking the energy from the fluid pushed by the impeller and transferring it to the transmission. The fins of the turbine face the opposite direction of the impeller, and when facing each other fluid can easily flow though the fins of the turbine. As shown in the image to the left, fluid enters from the outside of the turbine and is pushed inwards, to its center. In doing so the turbine begins to spin, thus spinning the output shaft attached to the transmission. Energy from the moving transmission oil has now transferred to the transmission. For an explanation as to why this occurs, click here.

StatorThe stator sits between the impeller and turbine in the center of the torque converter, directly in the flow of oil exiting turbine and entering impeller. The job of the stator is to correct flow direction of fluid before reaching the impeller. As fluid exits the turbine it is turning the opposite direction of the impeller. If this fluid was allowed to reach the impeller, it would counteract some of the rotational energy entering the impeller from the engine and reduce the output of the system. To fix this the stator's fins redirect the fluid at an angle of about 90 degrees, so it is flowing inline with the intake of the impeller. To minimize loses due to this obstruction of flow the stator is able to spin in the direction the torque converter spins, but not in the other direction, preventing it from spinning opposite the direction of flow and effectively creating a block in the system. Click here for a more in-depth explanation as to why this works.

|

The following video shows how TCI, a leading torque converter manufacturer, makes and rebuilds torque converters.