Enhanced Oil Recovery CO2 Injection

According to the U.S. Department of Energy, gas injection accounts for approximately 60 percent of EOR production in the United States. “In 2008 the EOR production through gas injection methods was around 566,000 bpd” (Andrei). With rising costs of fuel the challenges presented to the petroleum industry to increase oil recovery is growing indefinitely. The demand for innovations of EOR technologies are imperative for the nation to continue to grow and expand. With gas injection being a promising method among the four categories of enhanced oil recovery and today’s concern about releasing green house gases into the atmosphere; utilizing this excess carbon dioxide as a gas for injection has become a heavily researched and developing technology for EOR. Carbon dioxide gas injection has expectations to become a favorable and reliable method in the near future oil recovery when compared to the other gases injected into the reservoir during the tertiary gas injection phase.

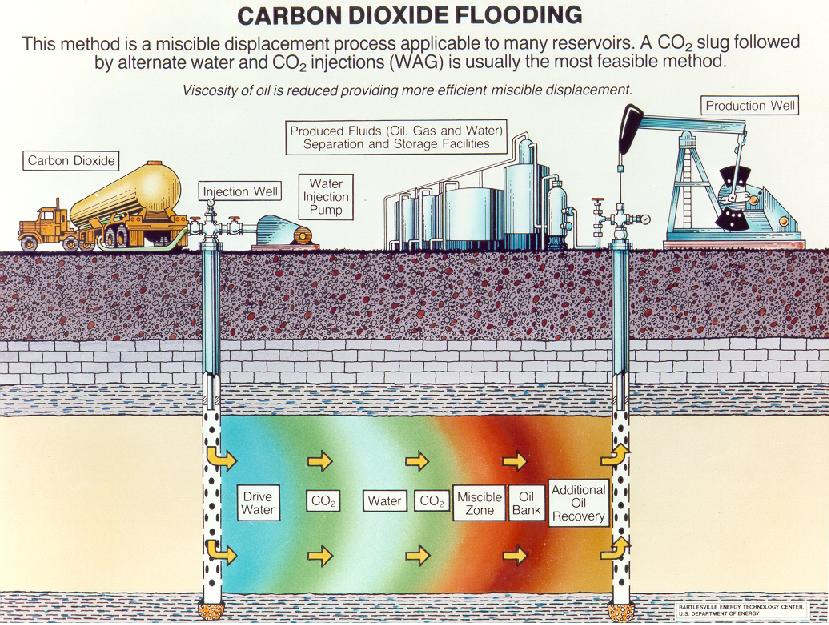

The process begins with CO2 purity of 95% to 99% which is first compressed, dried, and cooled before being transported and injected into the reservoir. Once injected into the formation and the mobility of the oil increases, the gas injected is usually chased by water since CO2 injection is essentially a costly method. During the miscible process CO2 requirement to mobilize the oil is approximately one to three tons of CO2 for one ton of oil produced and is increased to about three to five tons for immiscible processes. Approximately 30% to 70% of CO2 is produced with the oil and is separated, recompressed, and re-injected into the ground; the remaining carbon dioxide is sequestered into the formation. (Andrei)

Carbon dioxide EOR was first piloted in Scurry County, Texas in 1972. After being a successful technique in the Permian Basin of West Texas, Eastern New Mexico, and Southern Colorado, this technique is being pursued in other parts of the United States and around the globe (DOE). Up until recently the carbon dioxide used for injection was only economically obtainable from naturally occurring CO2in the reservoir. With today’s concern about excessive amounts of CO2 waste being released into the atmosphere causing a green house effect engineers have been devising ways to capturing and storing the carbon from facilities to prevent the gas from being released into the atmosphere. This CO2 can be used to inject into reservoirs where the gas does not naturally occur. However, the development of most of this is CO2 capture and sequestration is currently taking place.

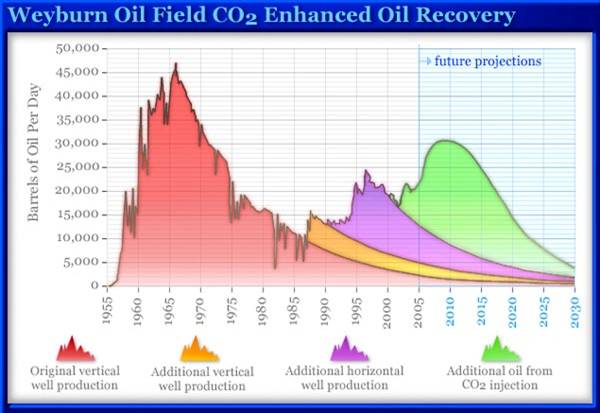

"One demonstration at the Dakota Gasification Company's plant in Beulah, North Dakota is producing CO2 and delivering it by a new 204-mile pipeline to the Weyburn oil field in Saskatchewan, Canada. Encana, the field's operator is injecting the CO2 to extend the field's productive life, hoping to add another 25 years and as much as 130 million barrels of oil that might otherwise have been abandoned." (DOE)

Advantages

- Low MMP of 2,500 psig

- Both Miscible and Immiscible

- Can recover heavy oils up to C30

- Promotes swellings which enables mobility

- Reduces viscosity of oil

- Increases oil density

- Reduced water density

- Soluble in water

- Reduces surface tension which causes greater oil displacement

- Helps the environment by providing a place for sequestration

Disadvantages

- Challenges of capturing and transporting CO2

- Asphaltene precipitation may cause clogging in the reservoir and reduce recovery

- Corrosive (shorter life for tubing)

- Viscous fingering (can by fixed by improving the sweep efficiency with water alternating gas "WAG")

- Expensive