Stereolithography

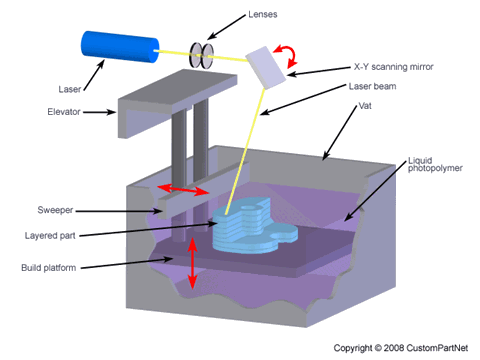

Stereolithography, just like any other 3d printer, is

an additive process, stacking layer by layer to create

an object. The stereolithography printer is very

different from its inexpensive cousin, the Extrusion printer. A laser

hardens a liquid photo-polymer (a plastic that hardens

when exposed to high amounts of ultra-violet light)

layer by layer.

The build platform moves down as the layer

hardens each layer. Rather than moving the laser, a

mirror directs the light which makes for a faster

process.

http://www.custompartnet.com/wu/stereolithography

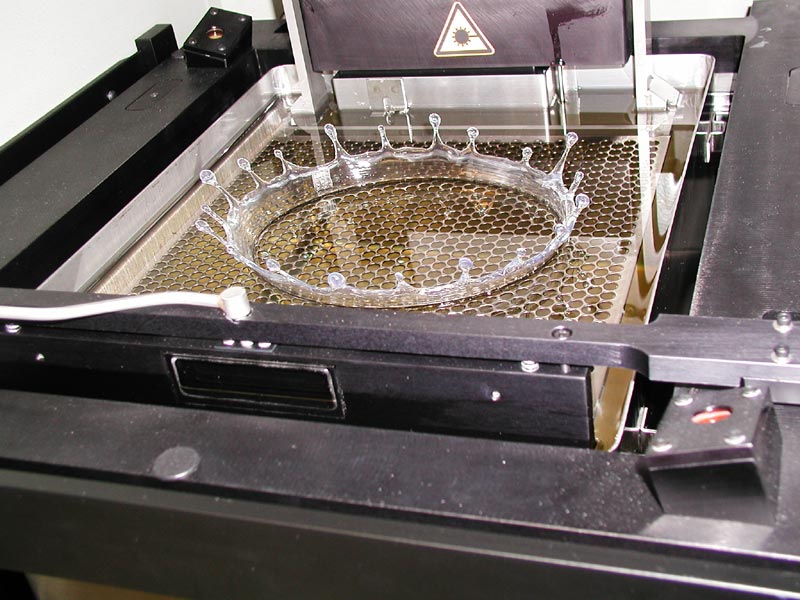

These printers are more expensive and

most often used in professional environments due to

their speed and accuracy.

Another key advantage of the Stereolithographic printer is its ability to create layers that are not supported by a layer beneath. For example, in the picture on the right, the "water droplets" do not have any other material underneath. This would be next to impossible to print on an extrusion printer.