Extrusion

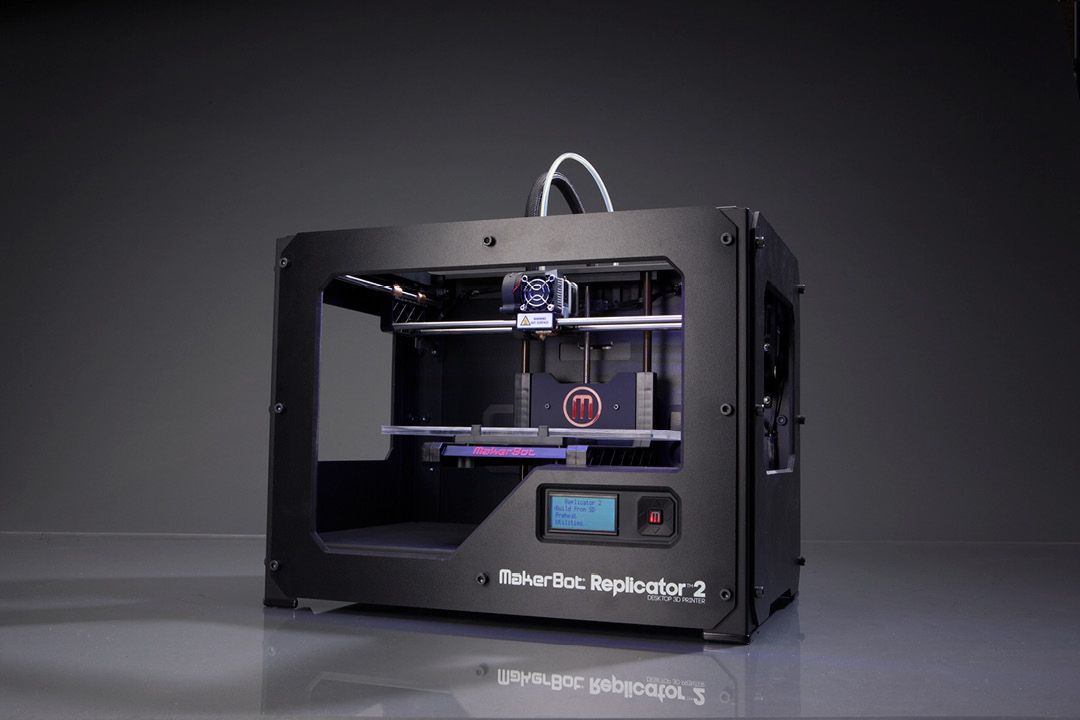

The most commonly seen type of 3d printer is the

extrusion printer. Effectively the "original" type of 3d

printer was the extrusion printer, created in 1984. This

type of printer melts plastic through a nozzle, laying

it carefully down on the previous layer as stepper

motors move the nozzle to designated x, y, and z

coordinates.

http://www.makerbot.com/wp-content/themes/makerbot/images/press/REP2_PRESS_15x10_low2.jpg

Above is a picture of one of the

best selling consumer 3d printers to date. The

MakerBot Replicator 2. Starting at around $2,000, this

printer is extremely affordable for its capabilities.

Soon extrusion printers will be a common household

item.

Some advantages of the extrusion printer are that it is generally less expensive than other types of printers. They have the potential to be highly customizable such as the extrusion printer "Reprap" that utilizes other 3d printers to create parts for the printer itself. The goal of the Reprap is to be able to print another printer, allowing for the exponential growth of the 3d printer. Undoubtedly a bright future.

Some advantages of the extrusion printer are that it is generally less expensive than other types of printers. They have the potential to be highly customizable such as the extrusion printer "Reprap" that utilizes other 3d printers to create parts for the printer itself. The goal of the Reprap is to be able to print another printer, allowing for the exponential growth of the 3d printer. Undoubtedly a bright future.

The mechanics of extrusion

printers are covered in the pages Mechanics, Physics Page 1, and

Physics Page 2