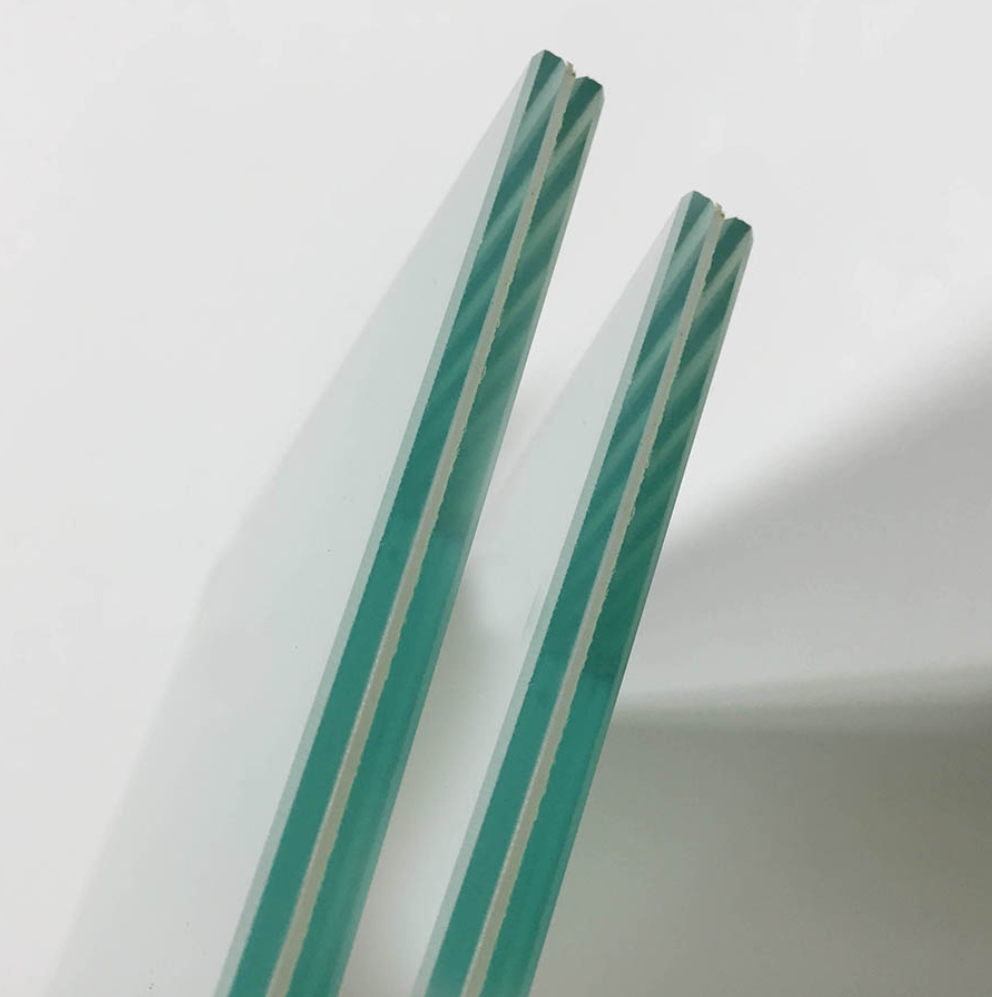

Laminated

glass is also made of the

expected materials (which I

describe very briefly here). Laminated

glass is two pieces of

regular glass with a layer

of something else between

them.

some different inserts

include:

- most commonly

polyvinyl butyral

- poly

carbonate (used in the

making of bulletproof

glass)

- ion-plastic

The insert (which generally

takes the form of a

resin/glue/film is fused of

the outer layers of glass

using heat of about 2552

deg. Fahrenheit, and

pressures upwards of 14 bar

(almost 14 times the

standard atmospheric

pressure).

Laminated glass can also be

made with tempered glass,

regular glass, colored glass

float glass, and etc.

laminated glass is also

considered a safety glass.

Due to the insert layer when

it is broken it cracks, and

the cracks spiderweb out

form the point of impact,

however the sheet of glass

does not fall apart because

the sticky resin/insert

layer hold it together. A

good example of laminated

glass is car front

windshields which can crack

but remain operational years

afterward.

Different insert can lend

the glass extra qualities.

For instance PVP (polyvinyl

butyral) laminated glass

is sound insulating and

filters UV waves. Other

inserts can result in

glass that can be used

for fire protection,

thermal insulation etc.

Generally laminated

glass can also be

layered with itself to

create a sort of double

decker sandwich effect.

The layer numbers used

are generally

2,3,5,7, and 9 (where

the numbers are the

number of glass panels

and between each set of

two class panes is an

insert layer).

|

source: Breaking

Laminated Glass on Vimeo

source: 55.1

clear laminated glass

manufacturer, 10.38mm clear

laminated glass supplier, clear

laminated glass manufacturer

(sggglassmanufacturer.com) |