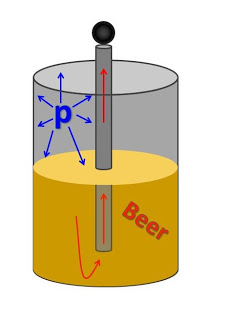

The modern beer keg is typically a stainless steel barrel used for the transportation and serving of beer; a large, straw-like structure known as the "spear" rests in the center of the barrel and is responsible for the release of gasses and movement of fluids from the keg once tapping occurs. The key to maintaining the body and proper gaseous presence for a good foam head at this phase is pressure. The beer itself already contains an amount of carbon dioxide (CO2) which is created over the course of the fermentation process. When it comes time to serve, air or additional CO2 is pumped into the keg; because the liquid itself is not compressible, pressure above the beer forces the fluid down and through the spear. As the air pressure outside of the keg is lower, beer flows out of the tap and the keg system's internal pressure equalizes.

Because the presence of carbon dioxide is so essential in preserving the integrity of brew, it plays an enormous role in the serving of that beer from the keg; to fully grasp this idea, we turn to the principles of Henry's Law: the amount of dissolved gas in a fluid is proportional to its partial pressure in the gas phase. As Dave Carpenter noted in his 2015 article Craft Beer and Brewing - The Physics of Foam, "Henry’s Law requires that any gas in solution remain in equilibrium with the gas in the headspace. If you think about it, it makes sense: [i]mbalance will result in gas diffusing into or out of solution until equilibrium is established. Atmospheric CO2 only exerts about 0.006 pounds per square inch (40 Pa) of pressure at sea level, which is nothing compared to the 12 to 30 psi (83 to 207 kPa) typically dissolved in beer. So carbon dioxide will rush out of a newly opened beer until the amount of CO2 in that beer is accordingly as low as it is in the atmosphere."

As the CO2 falls out of solution with the brew, it forms bubbles within the beer which attach to leftovers from the hopping and malting processes - these bubbles then rush to the head of the beer and form the foam head which persists as long as surface tension at the fluid ceiling permits it to. This froth is greatly responsible for the aromatic element in the tasting of beer due to the bubble attachments, so beers with an improper and low level of CO2 taste flat and those suffering from overtly high levels of CO2 may smell amazing, but taste terrible in drinking as most of the flavor has moved to the head.