|

(photo credit : http://www.tinfoil.com) |

The drive system of the Technics SP-1200 mk ii, later models, and copycat models, is truly an impressive site. Early turntables were operated by HAND CRANK, resulting in a massive distortion of any sustained pitch. Voices warbled, music was unlistenable. Finally with enough experimentation the relatively new consumer electric motor was now available, and the makers of phonographs had a constant drive. However, the drive was too irregular, so they added a lot of mass around the edge of the platter to utilize centripetal force to smooth out the fluctuations of the electric-belt drive. This drive combined with centripetal force smoothed out the rotation enough that a reliable record player was no possible. Early turntables spun 12" discs at 78RPM - at the time pressing and needle technology was primitive and the technology for dense pressings (like 45 or 33 RPM) were not available at the time. (of course we all know that the faster the record spins, the quicker the the record will be over, assuming that the grooves have the same width+spacing. So it was desirable to have records that spun slower yet still provided the high-fidelity that slower records had, from both an economics and marketing point of view) Soon 45RPM was available, and record players soon phased out the now useless 78RPM. 33RPM also came into existence quickly after 45, but too many singles continued to used the 45RPM format to phase that out, so record players just offer a button to adjust the speed of the tables rotation. In the classic belt-drive, this means just running the electric motor quicker, driving the belt and the platter at a faster rate. With the SP1200, invented in the late 70s, switching from 33 to 45 meant an entirely different thing. |

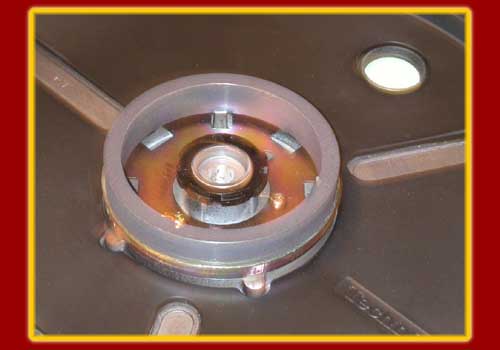

| The 1200's platter detaches, and on the bottom of the platter you will see a big fat ring of a magnet. The only place that it makes contact with the turntable base is at the center of the circle, and friction is kept to an absolute minimum using grease, low-friction elements, and very small surface area. When my turntables were shipped to me, and the platters were taken off the base of the turntable. Believe me I had quite a scare to see them disconnected! I hadn't noticed the magnet though, or the corresponding chain of coils wrapped around small magnets on the base of the turntable. This is the magic of the 1200 and is why this monster revolutionized dance music (okay well superior tonearm assembly as well and a variable pitch slider but... thats later) in America and throughout the world. |

|

|

To the PHYS 212 student it is apparent how the drive works, but let me explain it just for longevity's sake. The coils are wrapped around little magnets, each insulated from one another for a total of 10 or so coils around the circle. When the start button is pressed, the coils start a firing sequence that they will continue to run through until the power is cut or the start button is pressed again. These coils fire (on and off again over a relatively short amount of time) two at a time (one current positive, one negative) inducing a magnetic field, which will motivate the magnet on the bottom of the platter to move. A parallel to this would be to have a bar magnet on a spindle and another magnet below it separated by a small washer on the spindle. Take the bottom magnet and spin it (slowly for experiment purposes) and you will propel the other magnet in the same direction. This is the basic principle behind the SP-1200 drive. So when the 45 button is pressed, the timer on the solenoid firing controls simply shortens the delay between each sucessive coil triggering. Now of course, we also have the mass along the edge of the circle to smooth out the miniscule fluctuations in the magnet drive, but I assure you, this drive is phenomenal that the massed rims are only to sooth the egos of the inferior belt-driven turntables.

A new 1200 accelerating from rest will get to its desired RPM in about .5 seconds, and maintain it perfectly from that moment to the time you press stop. In the event that you do press stop, the coils fire in reverse and a new turntable will stop in a similar amount of time. (right now mine will actually end up with a bit of momentum in the opposite direction) An interesting phenomenon : as a turntable ages its start/stop time increases, that is to say, it will take more time for the turntable to accelerate to 'cruising' speed. (or decelerate to rest) The 1200s up at the local radio station KSUA are ancient monsters that take around 1.5-2 seconds to wind up to cruising speed and stopping is a joke. My hypothesis is that the wires wrapping the solenoids tire out (i.e. higher R value) and since I = V/R (V constant in this case) I tapers off a bit. That means that the EMF will be lower resulting in a slower acceleration time. |