A SAG mill is characterized by its large diameter and short length. It rotates, tumbling its contents violently , causing a breaking action. The mill is lined with wear resistant steel liners which are fitted with lifters to assist with raising the load. The liners are replaced as they wear and the lifting action has degraded. The load - dry ore, steel balls and water - occupies approximately 30% of the volume. The steel grinding balls represent 8% of this volume. Fresh ore is continually conveyed into the mill feed chute and is crushed until small enough to pass though the openings in the discharge grates. The feed rate is limited by the horsepower available to turn the mill and the and the maximum weight the hydrostatic trunnion bearings which support the turning mill shell can withstand.

The power to spin the mill comes from large electric motors coupled to mill shell through a clutch and gear system. These electricity consumed by these motors is the largest cost and inefficiency. Most of the power is converted to heat in the charge (load) and a small percentage into ore breakage.

The feed end of the 13000 hp Fort Knox SAG mill. The mill is driven by two GE horizontal synchronous variable speed motors,

one of which is depicted on the bottom right.

SAG mill feed is conveyed from the coarse ore stockpile. The ore passes through a gyratory crusher where it is reduced to 8 inch diameter before being dumped on the pile.

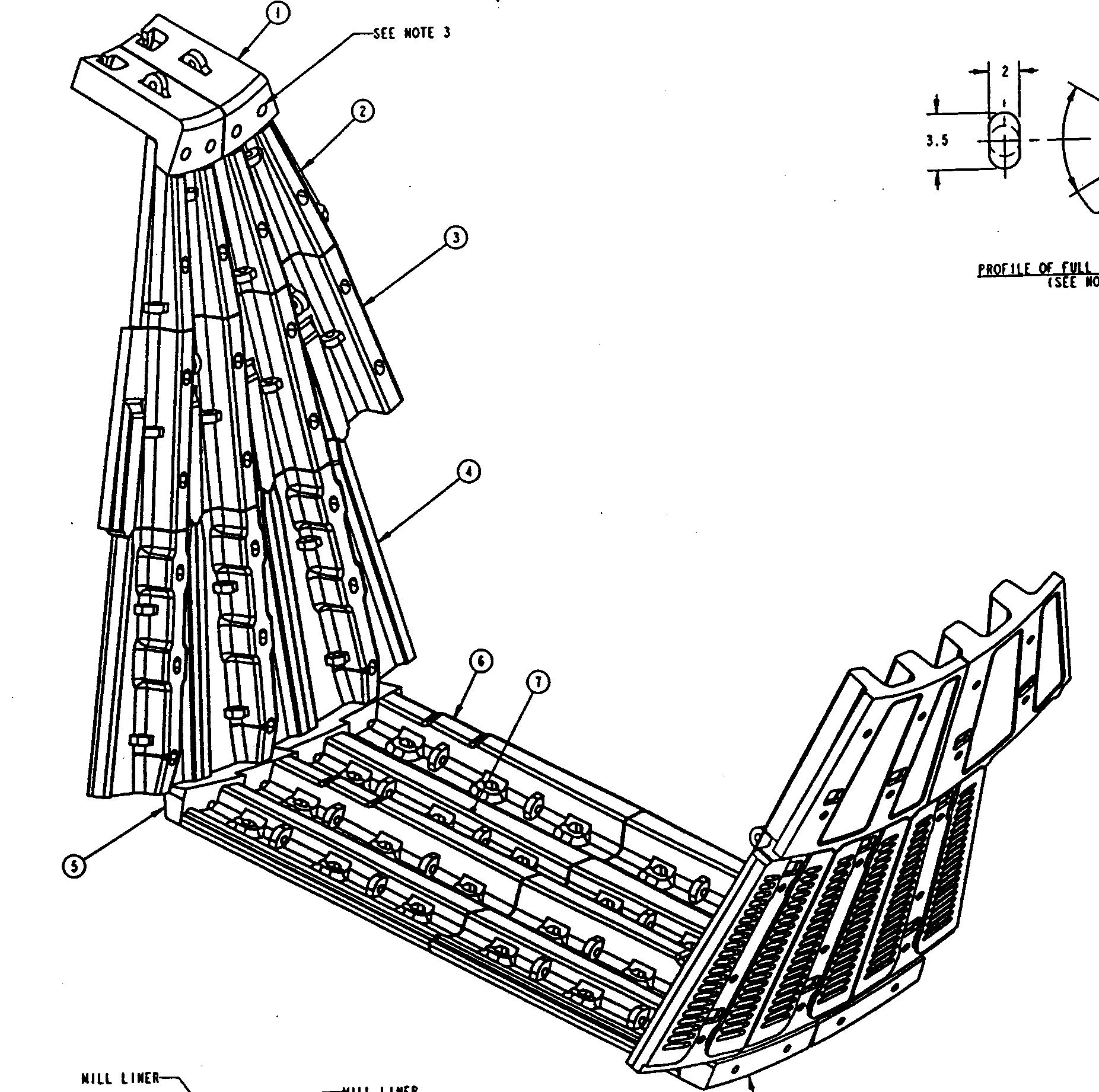

A line drawing of the Fort Knox SAG mill liner configuration and spare liners awaiting installation.

Five and one quarter inch steel grinding balls - cannon balls - occupy 8% of the mill volume and are consumed in the grinding action at the rate of 600,000 pounds per month.

The SAG mill and all other grinding equipment is remotely monitored and controlled via computer from a central control room. The control room operator watches four video terminals and a CCTV monitor to keep track of critical process variables impacting mill throughput.

all photos on this page courtesy of Fairbanks Goldmining, Inc.