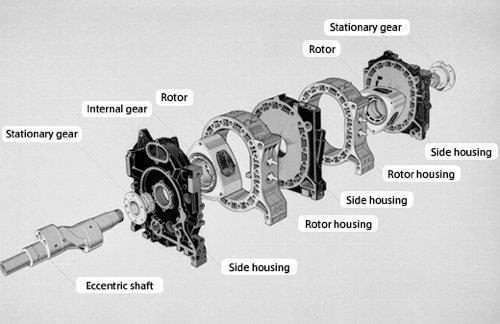

Instead of crankshaft there is

a eccentric shaft, which goes through centers of

both rotors and connects them. Both rotors

rotate around in orbital revolutions. To make

sure sure that the rotor makes a third of a turn

when eccentric shaft makes one, the rotors are

supported by ring gear, which is mounted onto

the housing of the engine plate.This also

prevents the rotor from rubbing the walls of the

housing.

One of the engineering

challanges with this engine was to seal

chambers. Here its much more complicated

compared to piston engine. Not only the

edges have to seal, but also the top and

bottom of the rotor. Thats where apex seals

come into play. They are locate on the very

edge of the rotor and on the top and

bottom.These are made out either coated cast

iron, aluminium-filled carbon or ceramic. In

order to maintain a good seal in low RPM

these seals have a spring under them, so

they are constantly pushed against the

housing.