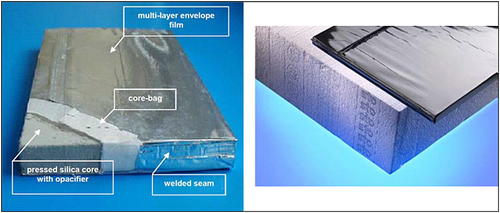

Image 6: Thermal conductivity vs. pressure of

air for materials with different pore sizes (Baetens et al. 2009).

The main appealing aspect of VIPs are their high thermal

performance, which is often several times higher than a

conventional insulator of a similar thickness. This means that

VIPs can be used in places where not much space is available.

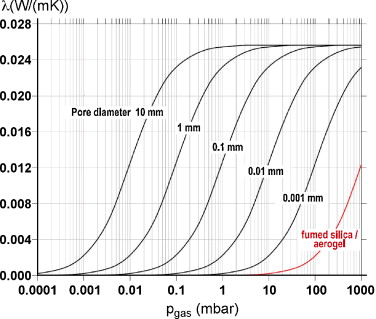

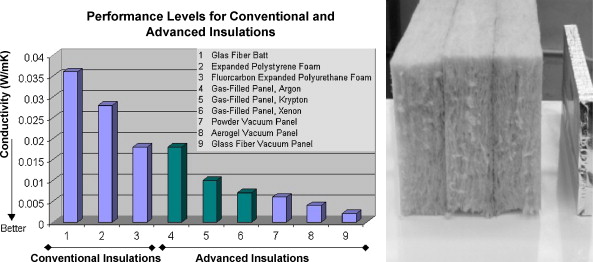

Image 7: on the left is a comparison of the conductivity of

some insulators, on the right is a VIP (in foil) compared to

the thickness

of glass wool needed for an equivalent thermal conductivity

(Baetens et al. 2009).

However, VIPs have several disadvantages compared to more

conventional insulators. One is the fragility of the panels. If

a panel is punctured, it will lose its low pressure environment,

and since VIPs are generally made much thinner than other

insulators, a punctured VIP will become a very poor insulator.

Because the seal on a VIP needs to be maintained, they must be

very carefully installed and once they are manufactured, as they

can't be modified without damaging the foil seal. Another

disadvantage of VIPs are their service life. Over time, VIP's

thermal conductivity will increase as a result of gas

penetration and water vapor penetration. While the service life

of a VIP depends on what type of core is used, a service life of

about 60 years is expected for a fumed silica core with a

multilayered aluminum envelope, and a service life of 10-15

years for an areogel with a metal foil envelope (Alotaibi,

Riffat 2013). This compares to other insulators like mineral

wool and fiberglass, which both have a service life of about 100

years. The last disadvantage of VIPs are their higher price

compared to other conventional insulation.