How Does It

Work?

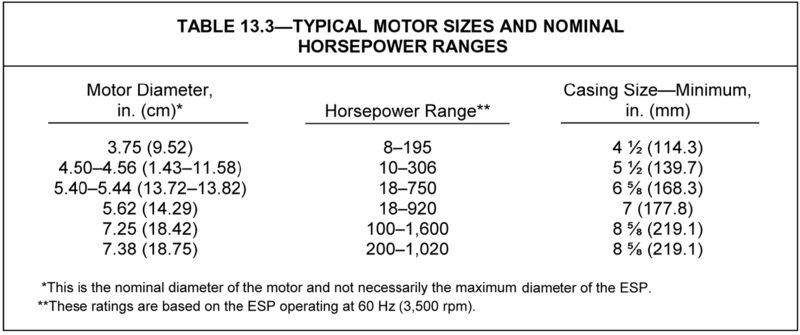

The Motor

The ESP's motor is a very specialized piece of

equipment that has taken years of development. The

motor which is very small in diameter, is able to

produce an enormous amount of power, which is

translated to the fluid.

How Does it work?

The pump is connected by a very large electric

cable to a surface unit. From this surface unit, the

operator can control the power input, which controls

the fluid flow rate. The motor turns roughly at

3,500 rpm which is about 60-Hz power. Most units can

operate between 230 and 5000 volts depending on

fluid needed.

How is it constructed?

"A wound stator comprises an unwound stator,

electrical windings, and insulation and

encapsulation systems. The unwound stator has

thousands of electrical-grade steel laminations

stacked in the housing and is compressed to hold

them aligned and stationary. The laminations are

die-punched with a center bore for the rotating

components to fit into and 18 winding slots for the

winding wire. Each slot is insulated with a

very-high-dielectric-strength polyamide insulation

material. This slot insulation provides

winding-to-stator (turn-to-ground) electrical

protection.

Insulated copper wire called "magnet" wire or "mag"

wire is then wound into each slot to form three

separate phase coils displaced at 120° intervals.

The insulation on the mag wire provides wire-to-wire

(turn-to-turn) electrical protection. Also, at the

end of the lamination stack, where the coil has to

make a 180° winding turn ("end turn"), insulation is

placed between the first winding phase and the motor

housing and then between each phase. This protects

for phase-to-phase faults.

After the mag-wire winding and insulation is

complete, the wound stator is then encapsulated with

either a solid-fill epoxy or varnish coating. The

encapsulation process fills the voids left in the

slots and around the end-turn coils. This provides

several important functions. First, it mechanically

holds the windings to resist movement that causes

wire-to-wire rubbing and possible damage to the

wire’s insulation. Second, it adds dielectric

strength to the slot winding and end turns. Third,

it significantly improves the overall thermal

conductivity for better heat dissipation from the

motor core through the slots to the motor housing

skin. And last, it protects the winding from an

attack by contaminates such as wellbore fluid. The

last two are less significant for the varnish

coating method. As its name implies, it is just a

thin coating, mainly on the surfaces of the

lamination slots and the mag wire, and has voids

where motor lubricating oil accumulates, reducing

both the thermal conductivity and the dielectric

strength. (ESP Motors)"

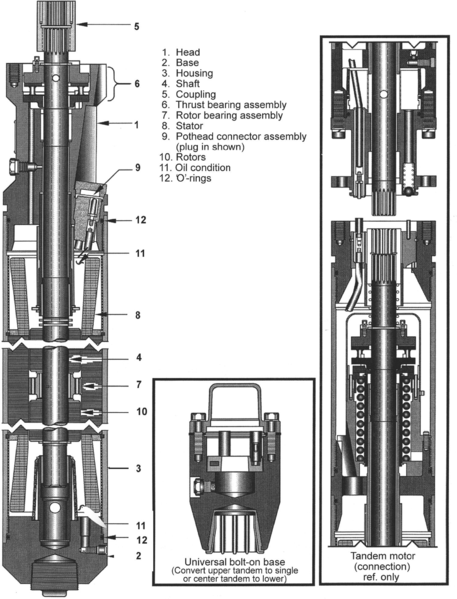

A diagram of an ESP motor.

http://petrowiki.org/ESP_motors

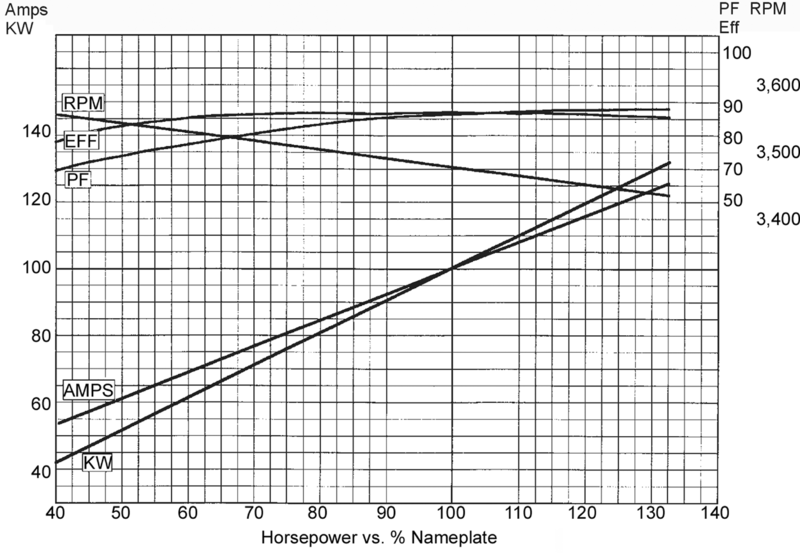

Performance of Motors

The performance of the motor is essential to the

operation of the pump. Below is a typical performance

curve, the calculation for horsepower, and the

calculation for efficiency.

Horsepower

Efficiency

C

= constant = 3,960, where Q is in

gal/min, and TDH is in ft [= 6,750, where Q is in

m3/D, and TDH is in m]

N = rotating

speed, rev/min

T = torque,

ft-lbf

Q = flow rate,

B/D [m3/d]

ηp = pump

efficiency

Performance Graph

http://petrowiki.org/ESP_motors

Heat from the motor:

Since the motor is operating at extremely high

rpm's and almost non stop, it generates a lot of

heat. Due to the motor being mounted underneath

the pump, formation fluids are able to come into

contact with the outer casing of the motor. The

heat is then transferred into the fluid. This is

good in two ways. It not only cools the motor, but

it heats up the fluid which makes it more viscous

and easier to pump, as well as handle on the

surface.

To see an animation of an ESP,

click

here.