This Picture Belongs to the Author of this page |

For those who are not familiar

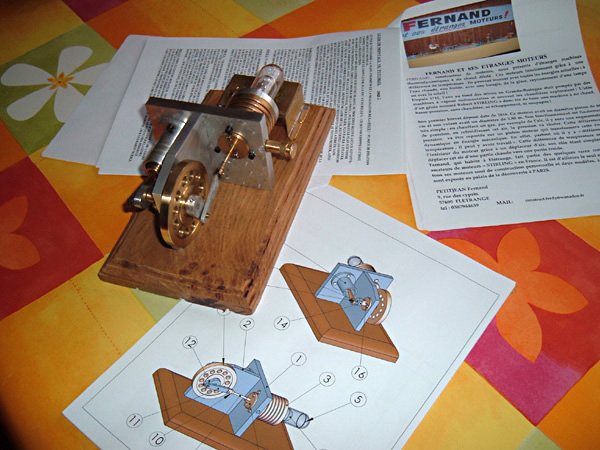

with Stirling engines or the parts that make it work here is a short

list and basic explanation. Parts (see picture, left):

1. Flywheel hub, displacer end of crankshaft, and displacer counter

weight. 2. Power piston end of crankshaft and piston counter weight. 3. Power piston (Airpot Pyrex cylinder and graphite piston) 4. Displacer gland (graphite lined aluminum), and displacer rod 5. Displacer (9/16 rigid blue foam), displacer cylinder (Lexan) 6. Displacer top plate (aluminum for good thermal conductivity) 7. Displacer bottom plate (aluminum for good thermal conductivity) 8. Displacer connecting rod (steel) 9. Power piston connecting rod (steel) 10. Flywheel (Lexan) The basic Stirling engine consists of: 'Displacer' (Parts 5,6,7, and working fluid- air). Parts 5 and 6, one hot, one cold, are the engines source of power. Part 5 (the actual displacer) Is designed to transfer the working fluid between relative hot and cold sides causing a cycle of expansion and contraction of the gas, thus a cycle of high and low pressures inside relative to the outside atmosphere. Power piston (3) When the inside air is cooled the piston is pulled down, and the opposite when the air is heated. This is what turns the crankshaft. Crankshaft (1,2). (On this engine it is a rotating assembly, but there is other ways of doing it) This part controls the motion of the displacer and piston. For all engines, the stroke of the piston and displacer run 90 degrees apart (or 270 depending on direction of heat flow). For a good example of this, see Wikipedia or one of the links below. http://en.wikipedia.org/wiki/Stirling_engine Please note that these three essentials can have many different forms and arrangements. They may look nothing like the ones on this engine. |

|

Alpha Engine

These are characterized by the use of two pistons and no displacer. One cylinder is cooled while the other is heated. Note the pistons on this engine are nearly the same size. |

| Beta Engine The Beta engine is more rare than the other engines due to its complexity of construction. One cylinder contains both the displacer and power piston. In these engines the power piston is typically doubles as the 'cold side' of the engine as well as serving the piston function. Notice the 2 sets of connecting rods going to the same point on the piston. This engine is water cooled and heated by a flame. |

|

|

Gamma Engine The Gamma type Stirling has a separate power piston connected to the displacer chamber by a tube, or mounted on the chamber connected by a hole in one of the plates. This is different than an alpha in that the volume of the power piston cylinder is only sufficient to serve as the total volume change in the displacer chamber. Also the power piston does not usually experience any heat transfer like an Alpha or Beta engine would.  |