Unfortunately applying hydraulics in real life isn't so simple.

There

are a few things to consider if you are planning on designing and building

hydraulic equipment.

Hydraulic System Analysis gave me some ideas on what to plan for.

The fluid to be used needs to have good lubricity, be chemically environmentally stable, a favorable viscosity, compatible with the metals that are going to be used, be readily available, low cost, foam, weight, etc. The fluid used is usually a type of oil. Water is not used for a few reasons. It leaks very easily (soaks into seals, gaskets), causes metals to rust.

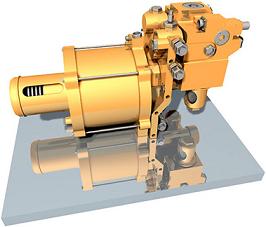

A source of power needs to be chosen in cases where high pressure is needed, basically a pump. The most popular types of pumps I found were gear, turbine and vane.

Hydraulic systems also include an accumulator (to store oil under pressure), a reservoir (a place to put excess oil) and relieve valves. Other parts include: pistons, rods, ports, snubber.

Hydraulic System Analysis gave me some ideas on what to plan for.

The fluid to be used needs to have good lubricity, be chemically environmentally stable, a favorable viscosity, compatible with the metals that are going to be used, be readily available, low cost, foam, weight, etc. The fluid used is usually a type of oil. Water is not used for a few reasons. It leaks very easily (soaks into seals, gaskets), causes metals to rust.

A source of power needs to be chosen in cases where high pressure is needed, basically a pump. The most popular types of pumps I found were gear, turbine and vane.

Hydraulic systems also include an accumulator (to store oil under pressure), a reservoir (a place to put excess oil) and relieve valves. Other parts include: pistons, rods, ports, snubber.

| Intro |

History |

How it Works |

Uses |

Bibliography |