Drawing from Dominion Engineering

Works Limited

Energy Concepts

Energy Concepts

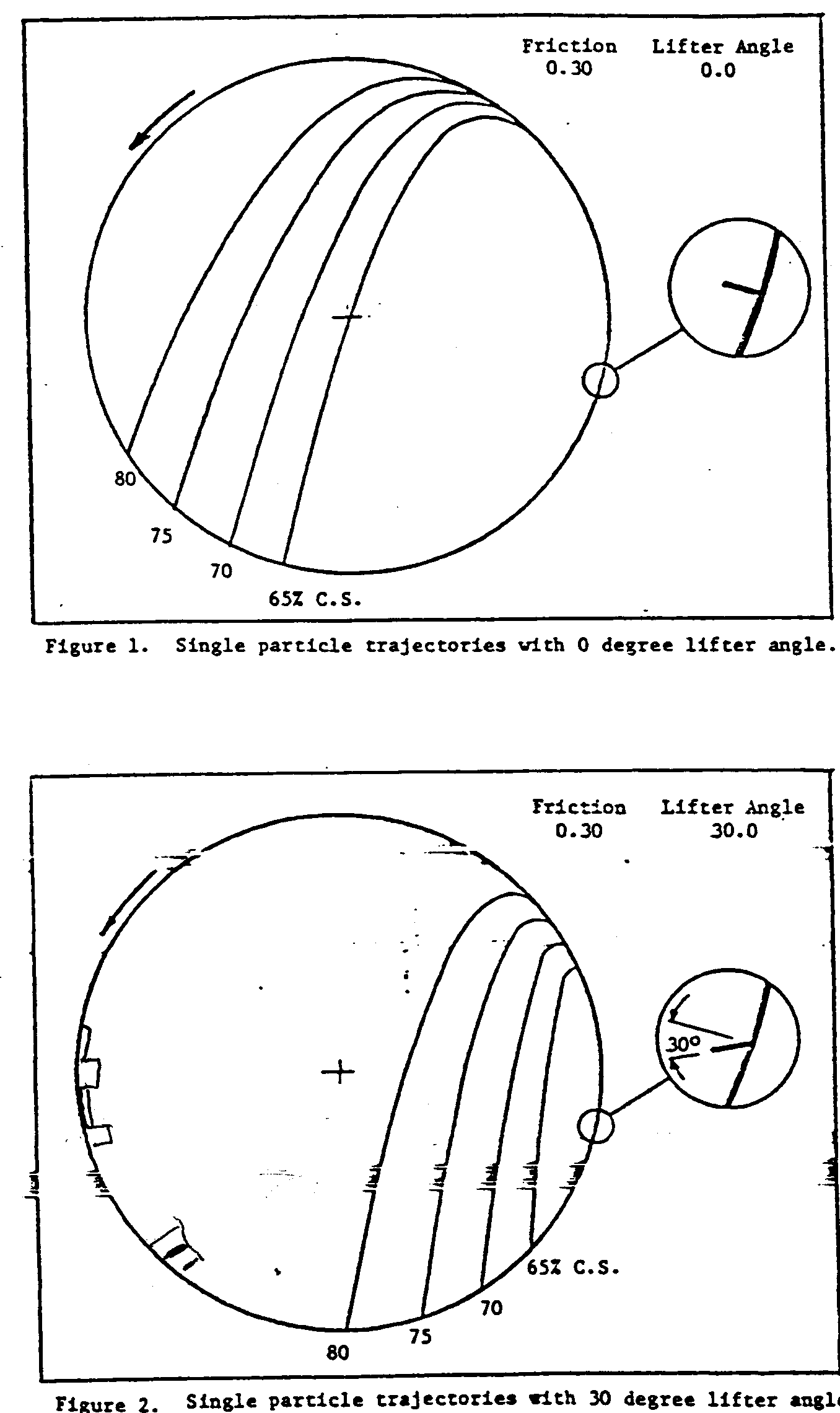

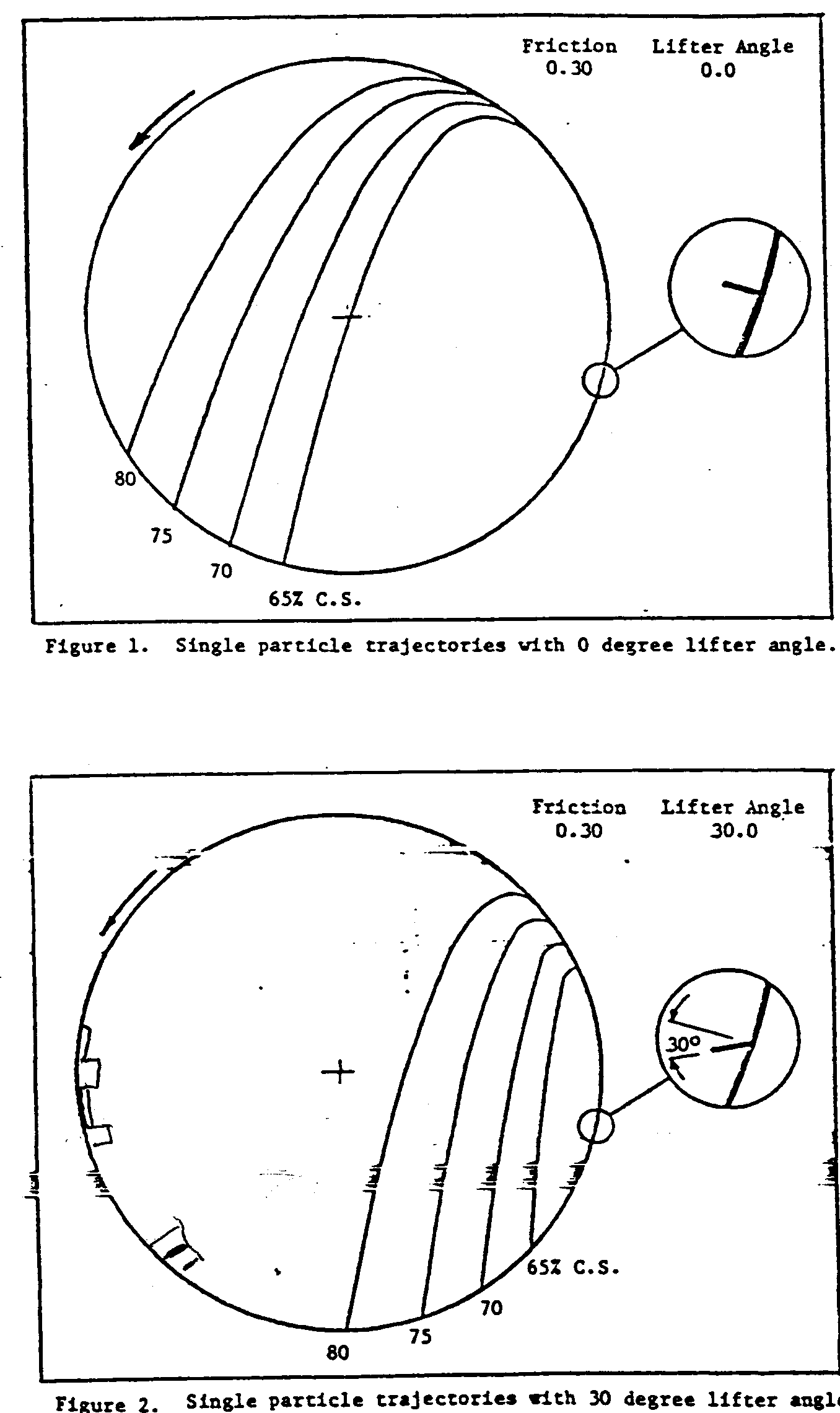

1. Liner design and rotational speed determine manner in which

energy is transferred to ore breakage.

2. Input energy is imparted to the grind load by motor causing

rotation.

3. The power draw will vary with different liner designs and throughout

the wear life and depends on the wear pattern.

4. The most efficient grinding occurs at maximum power draft - operating

the mill at its design

capacity.

5. Higher energy collisions - caused by greater trajectories are less efficient

than those is the lower energy range. Higher energy collisions cause liner

damming and increased grind ball consumption.

Mechanics

Ball and ore particles follow Newton's laws of motion.

1. A mill speed approaching 80% of critical can optimize grinding action

and reduce wear. A charge with a increased trajectory does less work and

more damage as grinding balls are flung against the opposite

side of the shell instead of falling down on top of the central mass.

2. Mill critical speed is reached when a particle centrifuges - hangs on

to the shell and does not fall.

3. Particle trajectory is independent of mill diameter and therefore optimum

% of critical speed is

independent of diameter

4. A desirable trajectory will not be maintained throughout the liner wear

cycle unless the the wear profile is predictable and can be compensated

by varying the rotational speed.

5. The trajectory of each particle is based on its geometry, dimensions,

and material properties of grinding balls, steel liners and ore type.

The KEY concept is liner design has most effect on charge

motion - particle trajectory - and

optimizing this charge motion can increase mill efficiency - reducing wasteful,

power

consuming

collisions.

DEM software simulated SAG charge

motion, Conveyor-Dynamics.com

Optimizing liner design requires a valid charge motion model.

The new DEM software, an image shown here,

describes the performance of independent mill styles

and liners configurations.

Energy Concepts

Energy Concepts