Waxing

Ski bases are created from the plastic polyethylene and created with a method

termed sintering. All modern bases are sintered which means that they are porous

and act like a sponge to the wax which is applied to them.

In general, softer ski waxes are used for warm temperatures. As the temperature drops there becomes a greater amount of dry friction between the snow and the wax. Harder waxes resist having sharp snow crystals imbed themselves into the wax which would slow the ski down.

The 4 traditional materials combined to make ski wax are:

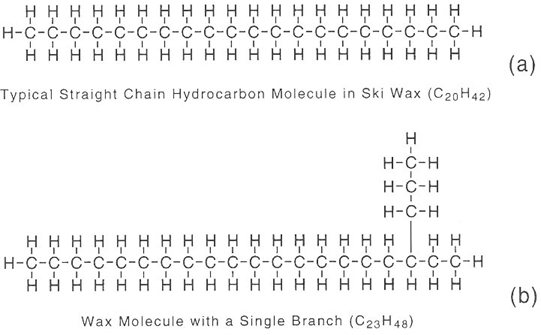

image from the Physics of Skiing

Cheaper, common waxes are composites of these ingredients. For better performance, higher end waxes combine these constituents with secret ingredients and these newer materials:

Kick wax is used to create friction to allow classic cross country skiers to push off the snow with one foot and glide with the other. Kick wax is designed have a high static coefficient of friction and a low kinetic coefficient of friction. The soft, tacky wax embeds the show crystals in its base through the force of the skiers downward kick. When the kick is finished, the skier transferes his weight to the other leg to make the next quick. Without any downward force, the forward motion of the ski lightly wipes the wax clean and ready to glide. This technique is detailed below: