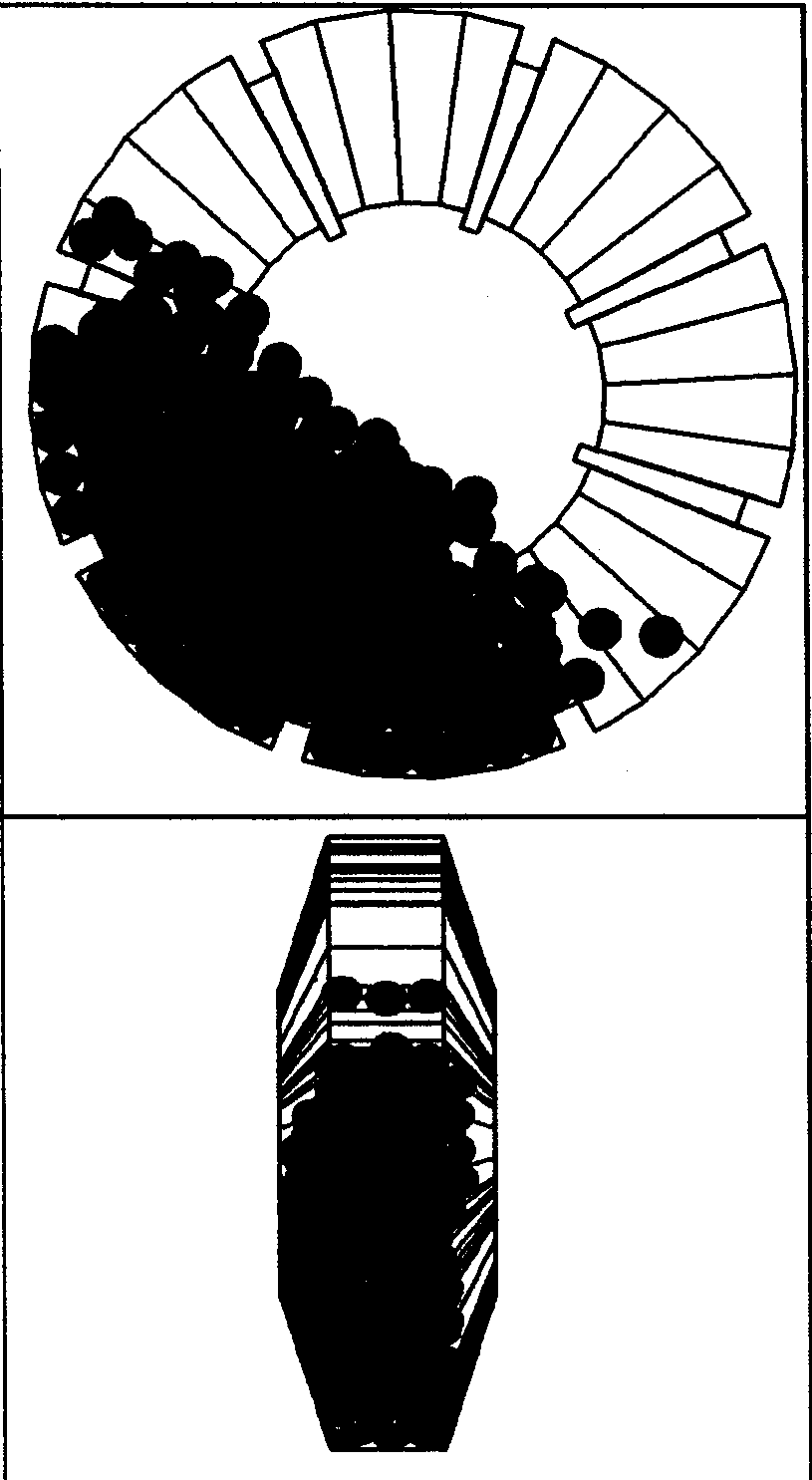

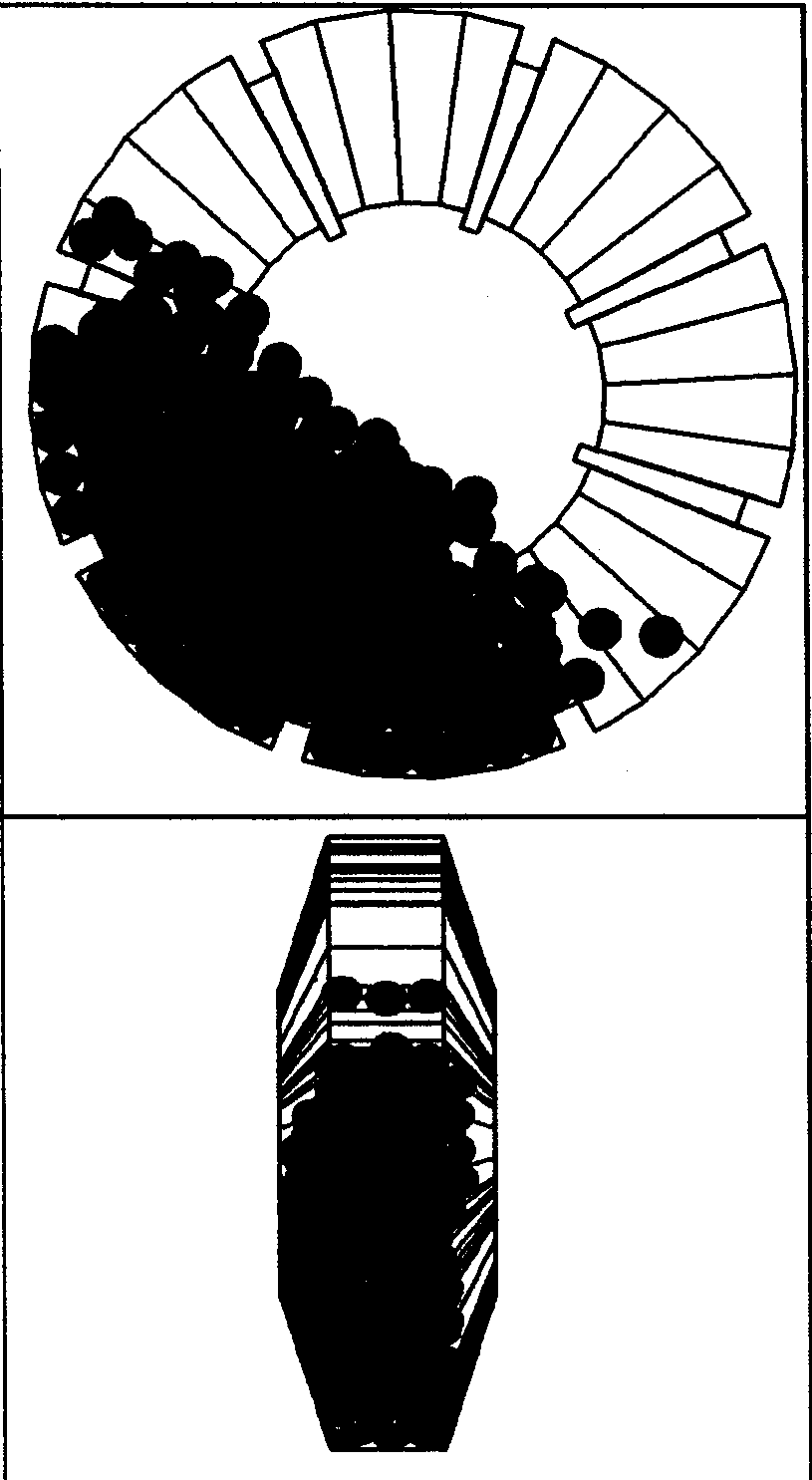

simulations which accurately depict the simultaneous motion of all particles raising and crashing inside the mill.

|

POWER HUNGRY

UNDERSTANDING CHARGE MOTION DYNAMICS INCREASES SAG MILL EFFICIENCY |

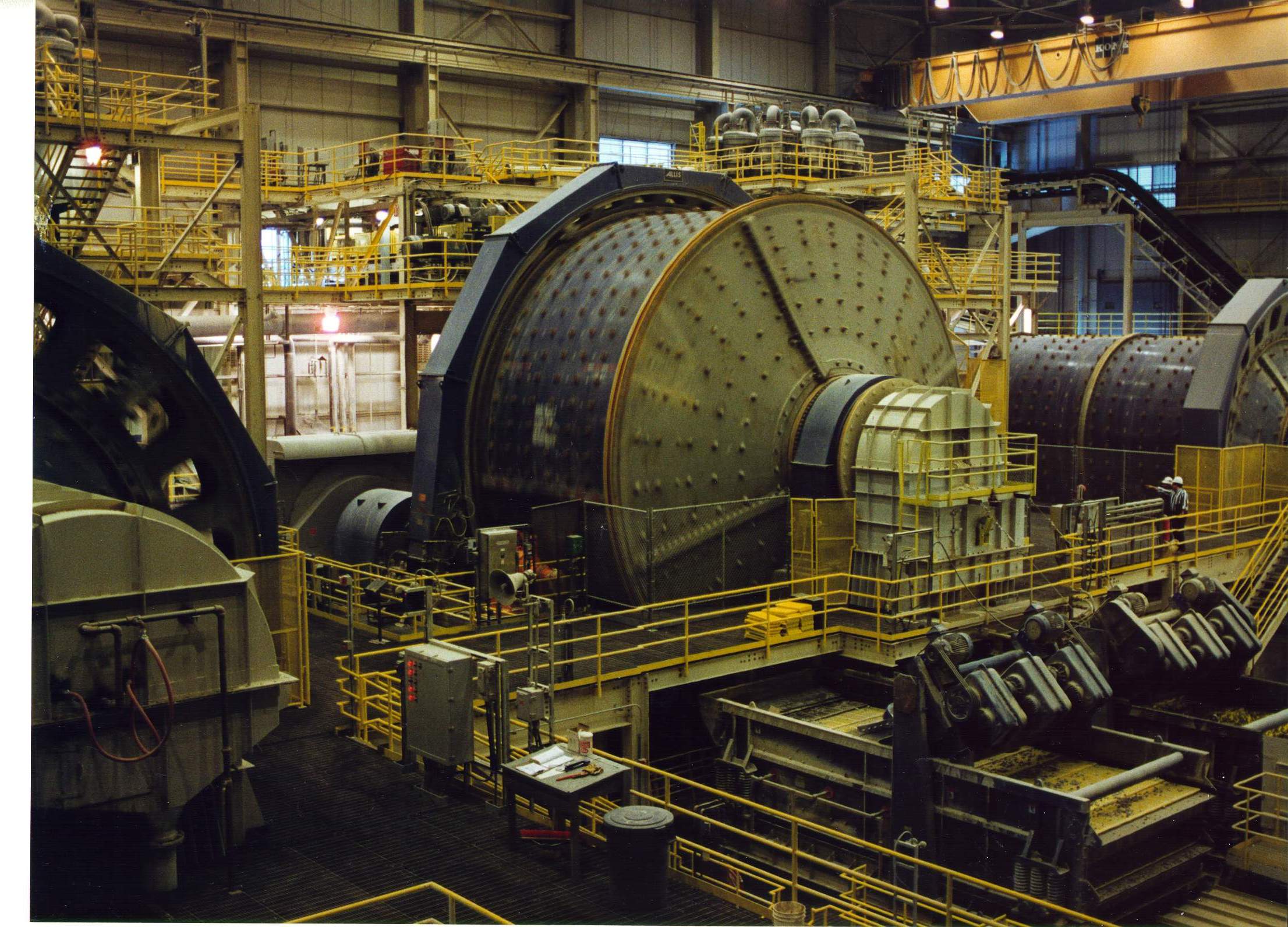

pictured to the right

smashes up to 55,000 tons of granite

pictured to the right

smashes up to 55,000 tons of granite From cement, to copper and gold production- raw material size reduction is a requirement and grinding mills, the final stage in this process, are the most expensive component to operate. Improvements in SAG mill operation offers the greatest potential for cost savings.

These improvements have arrived in the form of computer simulations and will change the way mills are designed

maintained and operated.

Photo courtesy of Fairbanks Goldmining, Inc. (Fort Knox Gold Mine)

Using discrete element method (DEM) mathematical modeling techniques and Newtonian mechanics, university and private industry researchers have developed 3D software

simulations which accurately depict the simultaneous motion of all particles raising and crashing inside the mill.