Over View of an Engine

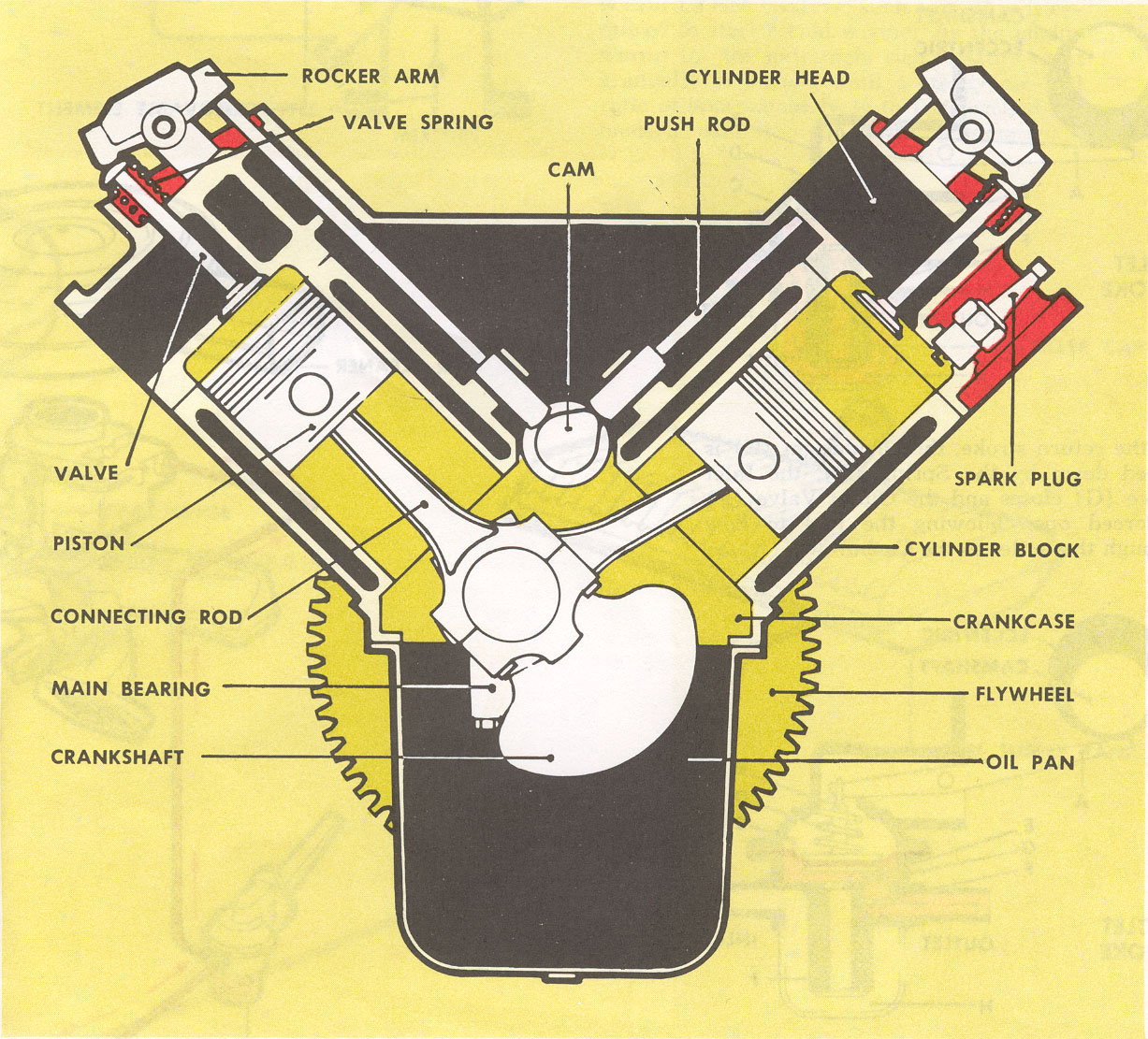

The CRANKSHAFT is a heavy steel forging that carries offset portions known as Cranks which describe a circular motion when in operation. Between each pair of cranks is a highly finished pin or Bearing Journal that carries the connecting rod bearing and piston assembly. As the piston and connecting rod assembly move in a vertical motion, the Crankshaft assembly, by means of the cranks and bearing journals, converts this vertical motion to rotary or circular motion. It is this rotary motion that is delivered to the Flywheel and other driving components and eventually to the driving wheels.

The FLYWHEEL is mounted at the rear of the Crankshaft. It's mass provides the inertia to carry the Pistons through the unproductive strokes of the cycle. In addition, it helps the engine run smoothly.

The CAMSHAFT is a strait shaft with a number of cams (one for each valve), accurately designed and precisely timed to lift each Valve at exactly the correct instant of the beginning of the intake and exhaust strokes, and to hold each valve open for the correct length of time required to fulfill each cycle in each Cylinder. At the front is the Camshaft Gear which is twice the size of the one on mounted to the front of the Crankshaft; thus for every two revolutions of the Crankshaft there is one revolution of the Camshaft.

The CRANKCASE is the biggest part of the engine and, together with the OIL PAN at the bottom, it forms an oil-tight housing in which all the rotating parts of the engine operate.

The CYLINDER BLOCKS are usually part of the Crankcase; they house the Cylinders, the Pistons and the Connecting Rods.

The CYLINDER HEADS are bolted to the block. Since water (coolant) must circulate from the Block to the Heads, a series of matching holes are provided in the Block and Heads. The Heads house the Valves, and the operating mechanisms, and the Spark Plugs. The Intake Manifold and Exhaust Manifolds are bolted directly to the Heads.

The VALVES have to preform under unusually difficult conditions. They are exposed to the extremely high temperatures generated in the combustion chambers, temperatures which often reach melting points for iron. They must be leak-proof even under tremendous pressures of the explosions and open and close as often as 2,000 times a minute.