TAR SANDS: A BRIEF OVERVIEW

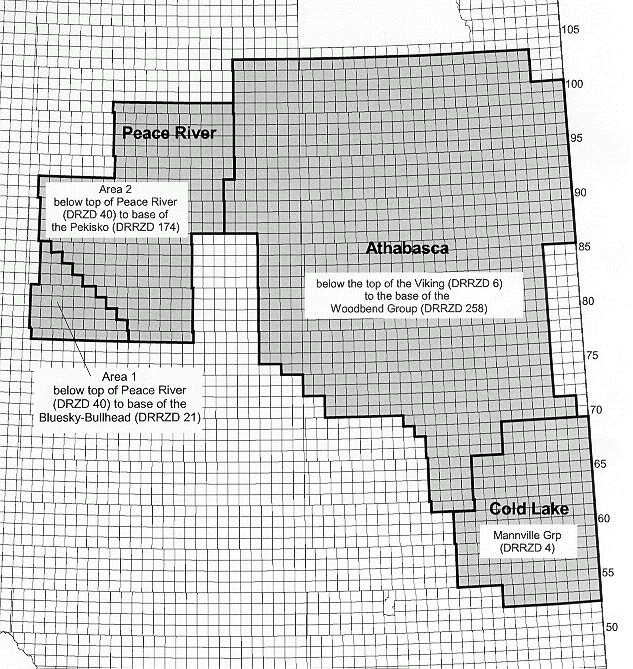

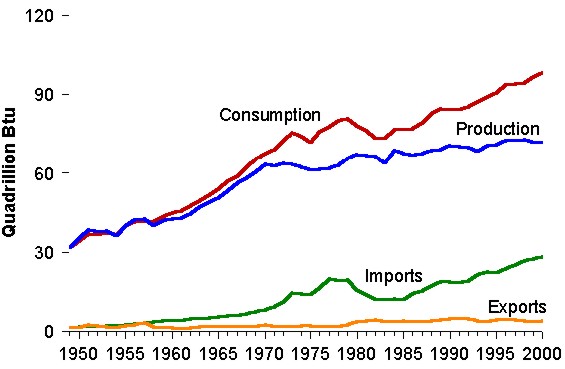

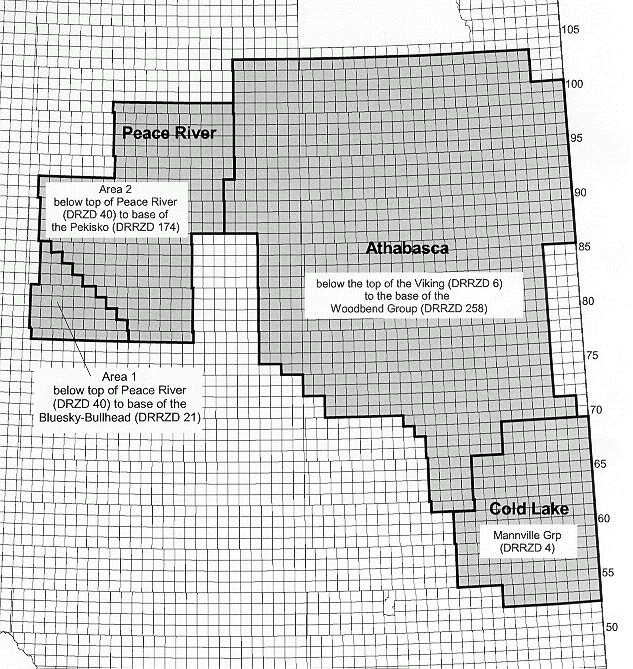

Tar sands are impregnated sands that yield mixtures of liquid hydrocarbon and require further processing other than mechanical blending before becoming finished petroleum products. Until recently Alberta's bitumen deposits were known as tar sands but are now called oil sands. Oil sands are deposits of bitumen; viscous oil that must be rigorously treated in order to convert it into an upgraded crude oil before it can be used in refineries to produce gasoline and other fuels. Bitumen is about 10-12 % of the actual oil sands found in Alberta. The remaining 80-85 % is mineral matter, including clay and sands, and around 4-6% water. While conventional crude oil is either pumped from the ground or flows naturally, oil sands must be mined or recovered in situ (meaning in place). Oil sands recovery processes include extraction and separation systems to remove the bitumen from the sand and water. Oil sands currently represent 40% of Alberta's total oil production and about one-third of all the oil produced by Canada. By 2005, oil sands production is expected to represent 50% of Canada's total crude oil output and 10% of North American production. Although tar sands occur in more than 70 countries, the two largest are Canada and Venezuela, with the bulk being found in four different regions of Alberta, Canada: areas of Athabasca, Wabasha, Cold Lake and Peace River. The sum of these covers an area of nearly 77,000 km2. In fact, the reserve that is deemed to be technologically retrievable today is estimated at 280-300Gb (billion barrels). This is larger than the Saudi Arabia oil reserves, which are estimated at 240Gb. The total reserves for Alberta, including oil not recoverable using current technology, are estimated at 1,700- 2,500Gb.

http://www.energy.gov.ab.ca/com/Sands/default.htm

| 2000 Statistics for Tar Sands | |

| initial volume in place: | 1.6 trillion barrels |

| Remaining ultimate potential: | 311.3 billion barrels |

| Production: | 605,000 barrels a day |

| Royalties: | 711.8 million (fiscal 2000-01) |

| Employment: (oil and gas): | 66,000 (direct upstream) |

| Investment: | 11 billion (1996-2000) |

| Investment: | 42 billion (2000 CAPP) |

Oil sands are substantially heavier than other crude oils. Technically speaking, bitumen is a tar-like mixture of petroleum hydrocarbons with a density greater than 960 kilograms per cubic meter. In comparison, light crude oil has a density as low as 793 kilograms per cubic meter. Mineable bitumen deposits are located near the surface and can be recovered by open-pit mining techniques. For example, the Syncrude and Suncor oil sands operations near Ft. McMurray, Alberta use the world's largest trucks and shovels (machinery) to recover bitumen. About two tonnes of oil sands must be dug up, moved and processed to produce one barrel of oil. Around 75% of the bitumen can be recovered and processed further. Processed sand has to be returned to the pit and the site reclaimed. Reclaiming a site means that the topsoil and muskeg are stockpiled so that they can be replaced as sections of the mined out area, or reclaimed. The rest of the overburden, clay and gravel, is used to reconstruct the landscape when mining is completed. For mining to be practical, in situ (in place) recovery techniques are required when the bitumen deposits are buried deep (more than 75 metres). Most in situ bitumen and heavy oil production comes from deposits buried more than 400 metres below the surface of the earth. Cyclic steam stimulation (CSS) and steam assisted gravity drainage (SAGD) are currently being used in in situ recovery techniques. Some other methods include thermal injection through vertical or horizontal wells, solvent injections and CO2 methods. Canada's largest in situ bitumen recovery project is located at Cold Lake. These deposits are heated by steam injection to bring bitumen to the surface, then diluted with condensate for shipping via pipelines.

There is some legislation involved with the oil sand recovery production in Canada. Oil sands operations emit carbon dioxide, a greenhouse gas (GHG), which is considered to be a contributor to climate change. Oil sand developers have been actively working to reduce CO2 emissions by 45% per barrel by 2010, compared to 1990 levels. Developers are required to restore oil sand mining sites to at least the equivalent of their previous biological productivity; which is to say that the region as a whole forms an ecosystem and landscape that is as least as healthy and productive as the one that existed before it.

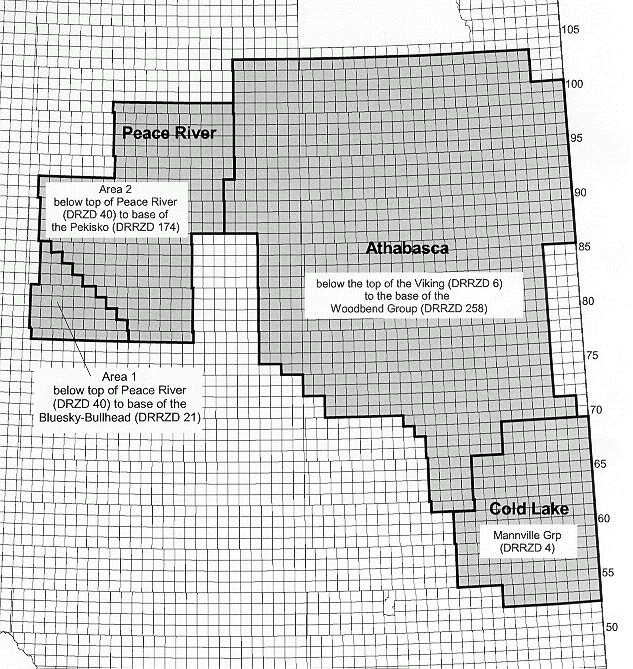

http://www.eia.doe.gov

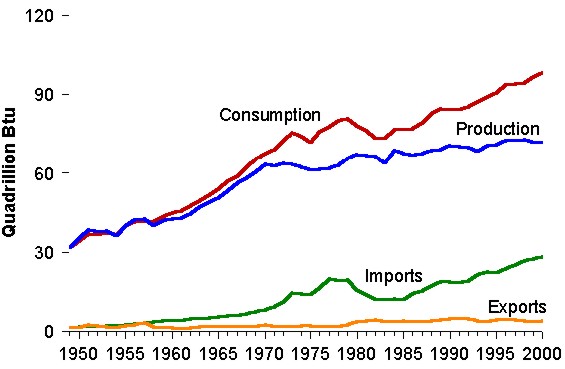

With the United States domestic decline in oil production, it is important to research possible tar sand production in America (Alaska). Our consumption continues to increase, as well as our dependence on oil imports. Today, about 59% of the oil consumed in the United States are imported. The deposits of oil sands (oil shale) in the United States are massive. The processing of oil shale has gone through cycles of development and commercialization, all without achieving a competitive cost of production. As well, tar sands are processed on a limited basis. An engineering study was done between the University of Alabama and the Department of Energy. This engineering study provided a preliminary design of a commercial processing facility to beneficiate 39,956 tons per day of run-of -mine eastern oil shale to produce 4.38million tons per year of concentrate. The report included a process plants design recovery of kerogen at 92%, which with `hydroretorting' would produce approximately 20,000 barrels of oil a day.

http://www.eia.doe.gov/emeu/cabs/usa.html

Matt Sexton

Physics 102

Newman